Vacuum Leak Tester

Simplicity and Performance

A vacuum leak tester is designed to meet the most demanding vacuum testing requirements.

%

of satisfied customers

years of expertise

+ vacuum box in service

mbar(-)

Our types of sealing box

Sealing box with cover

-

N14 standard sizes available

- NCustom sizes available

- NTop access

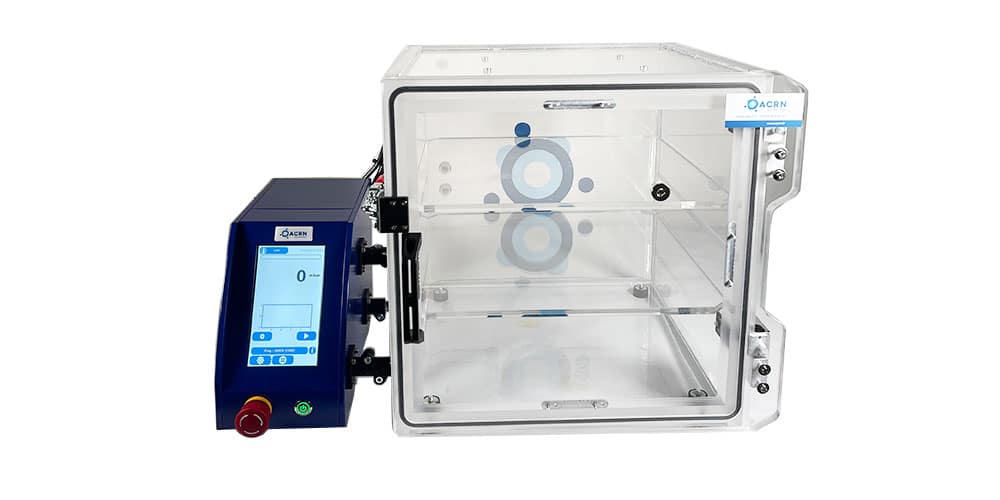

Sealing box with door

- N3 standard sizes available

- NCustom sizes available

- NEasy front access

Control box for sealing box

CTS

The CTS is a fully pneumatic vacuum bell model requiring no maintenance on the part of the operator.

This sealing box is intuitive and easy to use, thanks to its three-way valve. Quick, easy reading of results thanks to the needle manometer and the transparent vacuum bell.

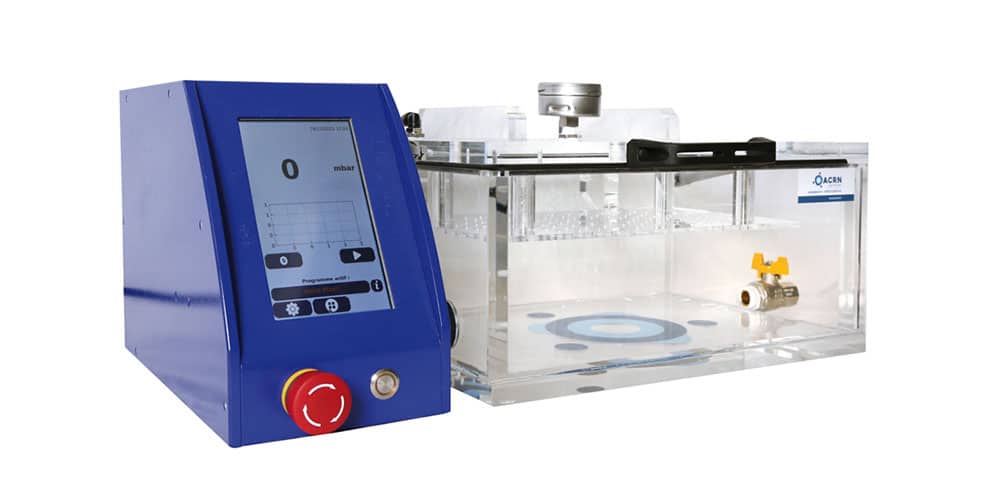

CTE

The 100% pneumatic dry seal box, operating solely with compressed air.

This model is advantageous because its test is fast, ergonomic and easy to use. It is possible to control the vacuum using a pressure reducer, but it is also possible to control the timing of the test.

The operator can stop the test at any time by pressing the emergency stop button on the front of the unit.

AGILEAK

New-generation device featuring a touch-sensitive control panel, with an intuitive, ergonomic menu for rapid user familiarization.

Operates with a compressed air network or vacuum pump for vacuum down to -950 mbar.

The AgiLeak offers a wide range of test options, including leakage, resistance and explosion tests, as well as the possibility of customizing tests.

All our models are compatible with door and lid box

Sealing box test methods

Dry test

- Suitable for liquid or semi-viscous products, such as perfume bottles

- Vacuum leak test.

- In the event of a fault, the product will leak.

Immersion test

- Used for packaging containing air, especially food trays.

- Method for identifying leaks by vacuum immersion in water.

- The presence of bubbles in the water reveals sealing defects.

Methylene blue test

- Ideal for products containing air in compact packaging, especially tablet blisters.

- Test based on return to atmospheric pressure.

- Leaks are detected by infiltration of a blue dye.

Options and Services

Printer

Print results on ticket

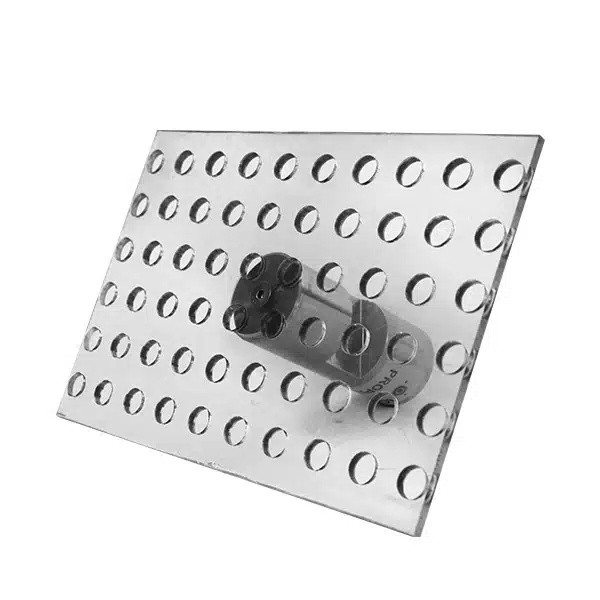

Immersion press

Attached to lid or free with handle

CFR 21

Compliance with regulatory standards for the pharmaceutical industry

Cart

Easy to move and handle in complete safety

Drain valve

Integrated drainage system for greater convenience

On–site installation

Full installation and commissioning service

User training

Full training on the use of the chamber

Qualification

Equipment Qualification Service

What our customers

Contact us

Need advice or a customized quote for our vacumm box?

At ACRN, we understand that every leak-testing need requires a customized solution. At ACRN, we understand that every leak-testing need requires a customized solution.

✅ Why choose our vacuum box tester?

✔ Robust, high-performance design for quality testing.

✔ Different sizes and configurations available to suit your needs.

✔ Technical support from waterproofing experts.

📩 Need a quote or advice? Fill in the form opposite to :

✔ Ask your questions.

✔ Request a personalized offer.

✔ Get tailored recommendations.

📞 An urgent request? Contact us on 02 32 80 81 40 or by e-mail at contact@acrn.fr.

We’re here to help you turn your plans into reality!

Frequently asked questions about the sealing box

What is the average service life of a sealing box?

The average service life of a sealing box is 10 to 15 years with proper maintenance. This time may vary according to use and maintenance.

What about delivery times?

Delivery times vary according to model. Standard boxes are available within 2-3 weeks, while custom solutions can take 6-8 weeks.

Do you offer training in the use of the vacuum leak tester ?

Yes, we offer comprehensive training courses for your teams, covering operation, basic maintenance and safety procedures.

What warranty options are available?

We offer a standard 2-year warranty on all our vacuum boxes.

How can I get a personalized quote?

Contact our sales team via the contact form or by phone. We’ll get back to you within 24-48 hours with a proposal tailored to your needs.