Torque meter

Control and reliability

Our torquemeters provide precise, reliable torque measurement to meet the most stringent testing requirements.

%

of satisfied customers

years of expertise

Torquemeters in service

%

Accuracy (±)

Discover our

NAA torquemeter

The NAA torque meter gives you fast, reliable torque control. Compact and ergonomic, it facilitates quality control and ensures full compliance with industrial standards. Ideal for optimizing your audits and reducing non-quality costs.

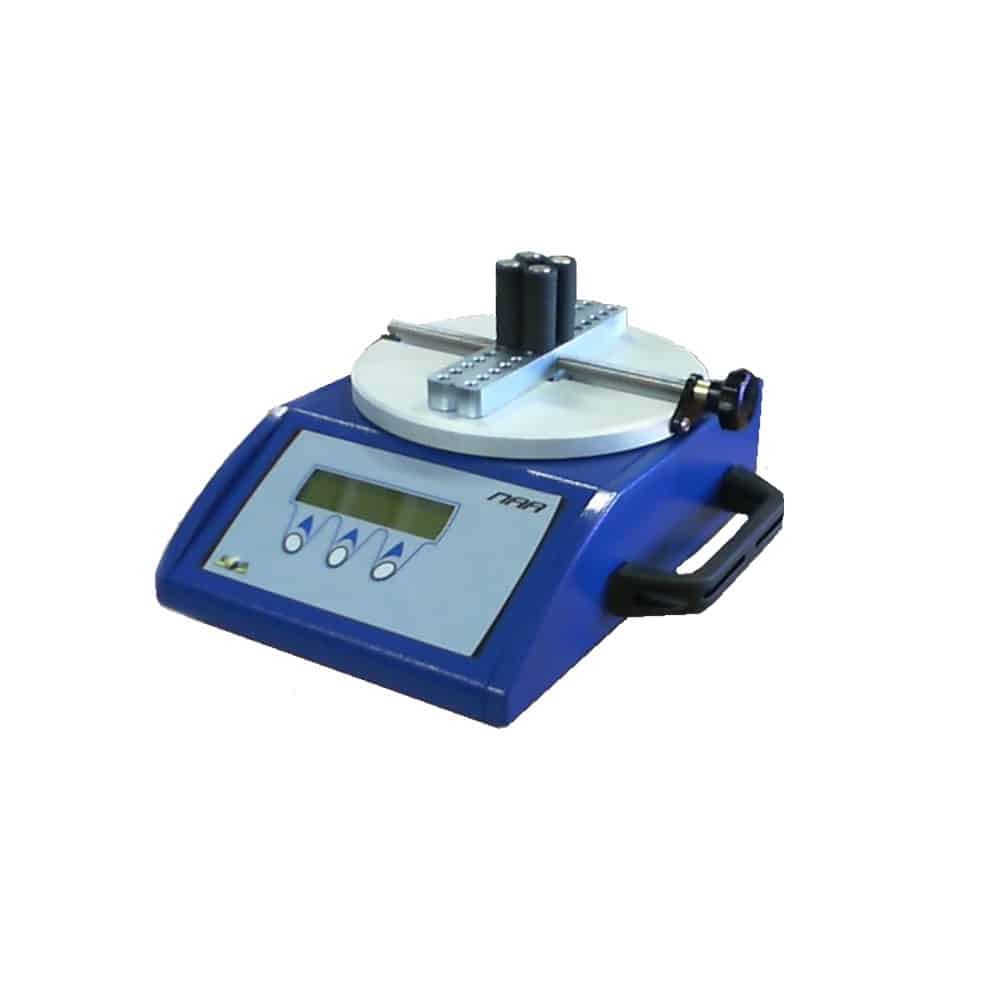

NBA torque meter

Designed for production environments, the NBA electronic torque meter is the choice of many packaging manufacturers for measuring the screw-in and screw-out torque of their products.

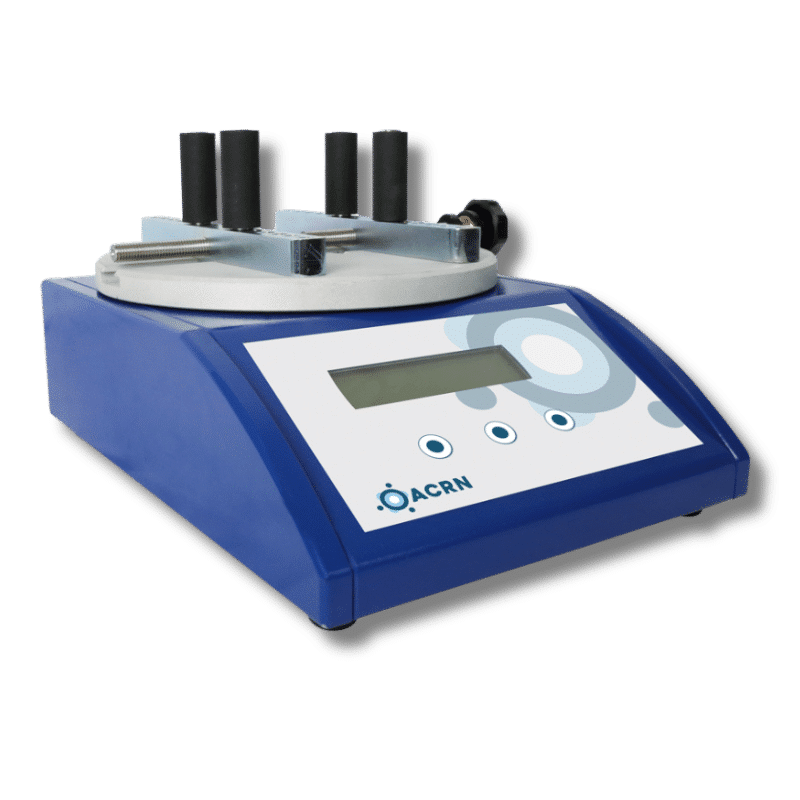

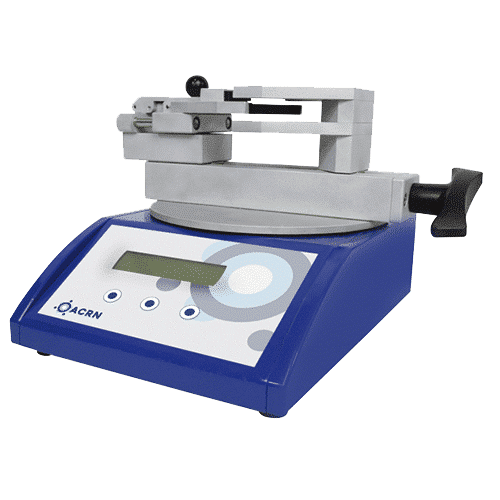

NCA torque meter

The NCA tabletop torquemeter guarantees precision and simplicity for all your workshop quality checks. Ergonomic and reliable, it ensures full compliance with ISO standards while facilitating your audits thanks to its clear, intuitive display. An essential ally for controlling your industrial processes!

Torquemeter software features

Any tests to be carried out on doypacks?

Our manual torque meters offer a reliable and intuitive solution for measuring screw-in and screw-out torque. However, to meet increasing demands for repeatability and ease of use, you can upgrade your manual torquemeter to a motorized version with the RepeaTork.

This motorized torquemeter has all the functions of a manual model, but with the addition of controlled motorization to guarantee more consistent, precise and reproducible measurements. It has three operating modes adapted to the needs of packaging manufacturers:

✅ Simple mode: conventional screw/unscrew,

✅ Advanced mode: control by angle or torque,

✅ Quality mode: opening torque check followed by torque tightening.

Thanks to this evolution, you benefit from considerable time savings, while ensuring more rigorous quality control in line with market standards. This solution has already been adopted by many players in the cosmetics, pharmaceutical and food industries, who are looking for both reliability and efficiency in their control processes.

Tightenings compatible with our torque meters

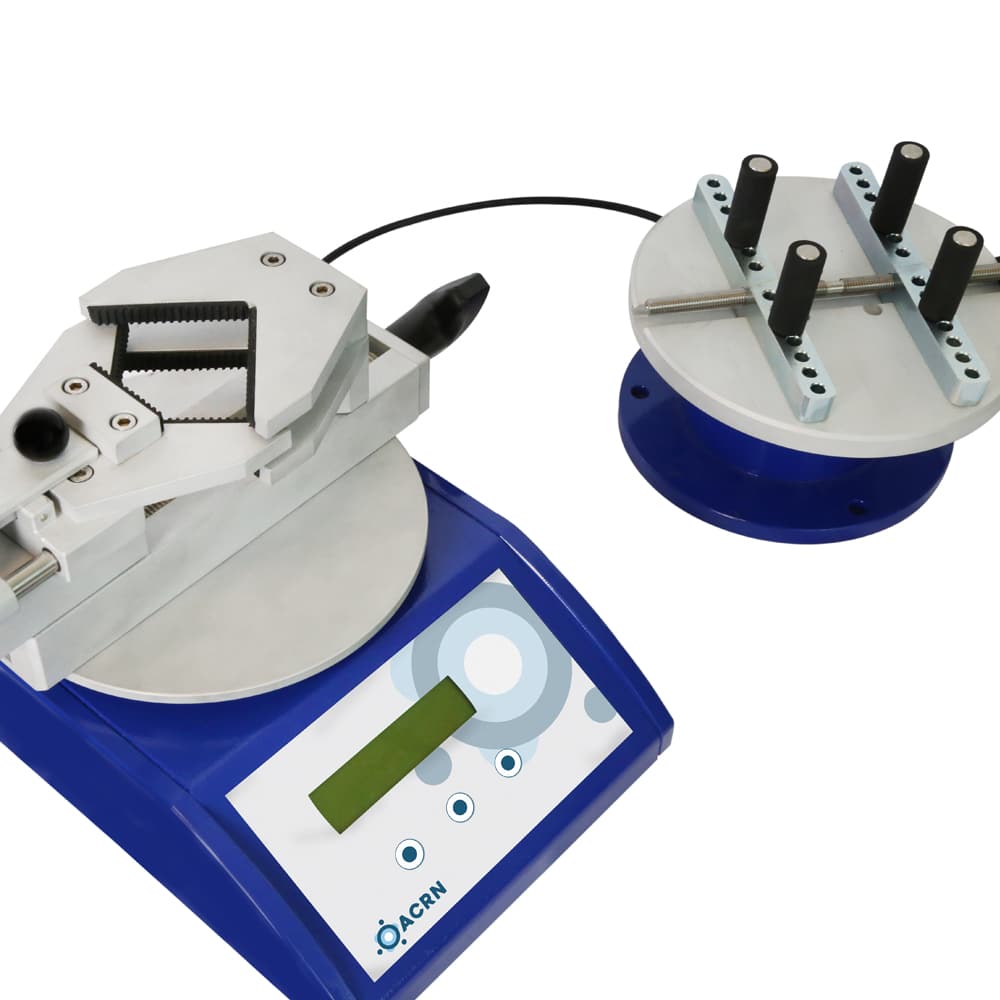

4- Studs Clamping

The 4-stud clamping is an agile and economical gripping system. Thanks to its two adjustment bars, it allows botlles of all sizes and shape to be kept in a centered position.

There are two types of studs: the smooth studs and the screw studs.

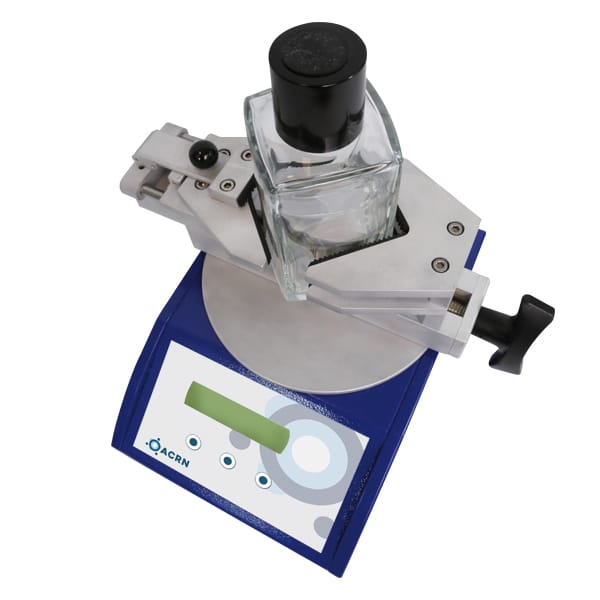

V-jaw clamping

They can be used on all manual or motorized ACRN torquemeters. Very versatile, they can also be installed on traction bench to hold objects for traction or compression tests.

Can clamping

The canister clamp, with its platform and off-center studs, holds canisters of all shapes and sizes in position and ensures the centering of the cap on the sensor.

It’s removable and attaches to the 4-pin clamping bars, making it easy to switch from one to the other.

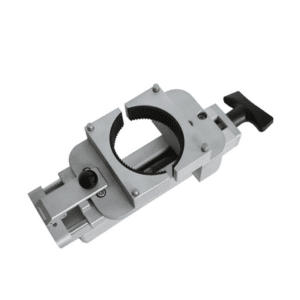

Quick clamping with interchangeable jaws

Quick clamping with interchangeable jaws hold in place

to position jars or bottles without damaging them.

Bottle clamp

This support holds wine bottles securely in place. Its height is customizable, and it adapts to both large and quick-action clamping systems.

V-jaw quick-clamping

The rapid concentric V-jaws gripping allows objects to be maintained without distorting them. Rubber bands prevent marking and therefore damage to the test sample.

Options and accessories

IP/Ethernet connection

Easily integrate your torque meter into a connected environment thanks to networked data transmission. Instantly share results with your teams and automate reporting.

Data Xport

Optimize analysis of your results with dedicated software for automatic export of measurements. Ideal for detailed monitoring and efficient statistical processing.

Matrix and thermal printers

Make it easy to archive and track measurements with instant printing. Choose between a robust matrix printer or a fast thermal printer for test reports directly after each measurement.

External sensor

Benefit from increased flexibility by controlling multiple torque ranges with a single device. Change sensors to adapt your measurements to different industrial requirements.

Carrying handle for torquemeter

An ergonomic handle makes it easy to move your machine. Ideal for mobile use in laboratory or production.

Plug operating tools

Ensure greater measurement repeatability with specially designed tools for precise cap handling and tightening.

What our clients

Contact us

Need advice or a personalized quote?

At ACRN, we know that every application requires precise, customized solutions. Our torquemeters, whether new or adapted to your existing equipment, are designed to meet your quality and performance requirements.

✅ Why choose our torque meters?

- Unrivalled precision for reliable measurements.

- Customized options to suit your specific needs.

- Technical support from experts in the field.

Please fill in the form opposite:

- Ask your questions.

- Ask for a quote.

- Seek expert advice.

📞 An urgent question? Contact us directly on 02 32 80 81 40 or contact@acrn.fr.

We’re here to help you make your projects a success!

Frequently asked questions about the torquemeter

What is a torquemeter?

A torquemeter is a high-precision torque measuring instrument used to measure the torque of a system. The term “torque” refers to the rotational force applied to an object. Torque is measured in units of Newton-meters (Nm) or pound-feet (lb-ft) and is often used to describe the rotational capacity of a motor or gear. These devices, often referred to as torquemeters, are indispensable in fields such as engineering, automotive and construction.

A torque meter measures the torque of a system, which is an important physical quantity in many fields such as engineering, mechanics, automobile construction, etc.

Torquemeters can be analog, but the vast majority of torquemeters are electronic.

What other names are used to describe a torquemeter?

The torquemeter is known by several names, which vary according to the field of application or language. Common synonyms include: torque wrench, torque screwdriver, torque tester, torque controller, torque meter. In English or in an international technical context, the terms torquemeter or torquemeter are also used. All are tools designed to precisely measure torque, i.e. the rotational force applied when screwing.

What's the difference between a torquemeter and a torquemeter?

There’s no real difference between a torquemeter and a torquemeter: both terms designate the same type of tool. The word torquemeter is simply an adaptation of the English term torquemeter (or torqmeter), used in international or technical contexts. The French term couplemètre refers to torque measurement. Whatever the name, it’s an instrument designed to precisely control the rotational force applied to a nut, screw or axle.

In which sectors are they used?

Torque gauges are used in many sectors where precise tightening is crucial. They can be found in the automotive industry (engine assembly, quality control), aeronautics, manufacturing and industrial maintenance, but also in the medical sector (for implantable devices or prostheses) and renewable energies (wind turbine assembly, for example). Whether in production, quality control or maintenance, torquemeters help guarantee the safety, performance and reliability of mechanical assemblies.

What are the advantages of ACRN torquemeters?

ACRN torque meters are distinguished by their accuracy, reliability and ruggedness, even in demanding industrial environments. Designed to meet the needs of inspection and maintenance professionals, they offer fast, reliable torque measurement with excellent repeatability. ACRN equipment is also ergonomic, easy to use and compatible with different types of industrial screwdrivers. Thanks to its responsive customer service and high-quality French manufacturing, ACRN has become a benchmark in the field of industrial torquemeters.

Is the torque test easy to deploy?

Yes, the torque measurement test is generally easy to set up, especially with a suitable torque meter. Modern models, like those offered by ACRN, are designed to be intuitive and quick to use, without the need for complex training. Often, all you have to do is connect the tool to the screwdriver or system to be tested, start the measurement and then interpret the results displayed. Some torquemeters even feature automatic data logging, facilitating quality monitoring and control traceability.

What else does a torquemeter do?

In addition to torque control, the torquemeter can be used in many industrial and technical contexts. For example, it allows you to :

-

Check the conformity of screw connections at the end of the production line,

-

Check screwing tools (screwdrivers, torque wrenches) for wear or drift,

-

Ensure the safety of mechanical assemblies, by avoiding under- or over-tightening,

-

Calibrate other torque measuring equipment,

-

Carry out R&D tests on screwing or material performance.

This makes the torquemeter an indispensable tool for quality control, preventive maintenance and product development.