ATS-X Tube Seal Testers

The electronic precise model

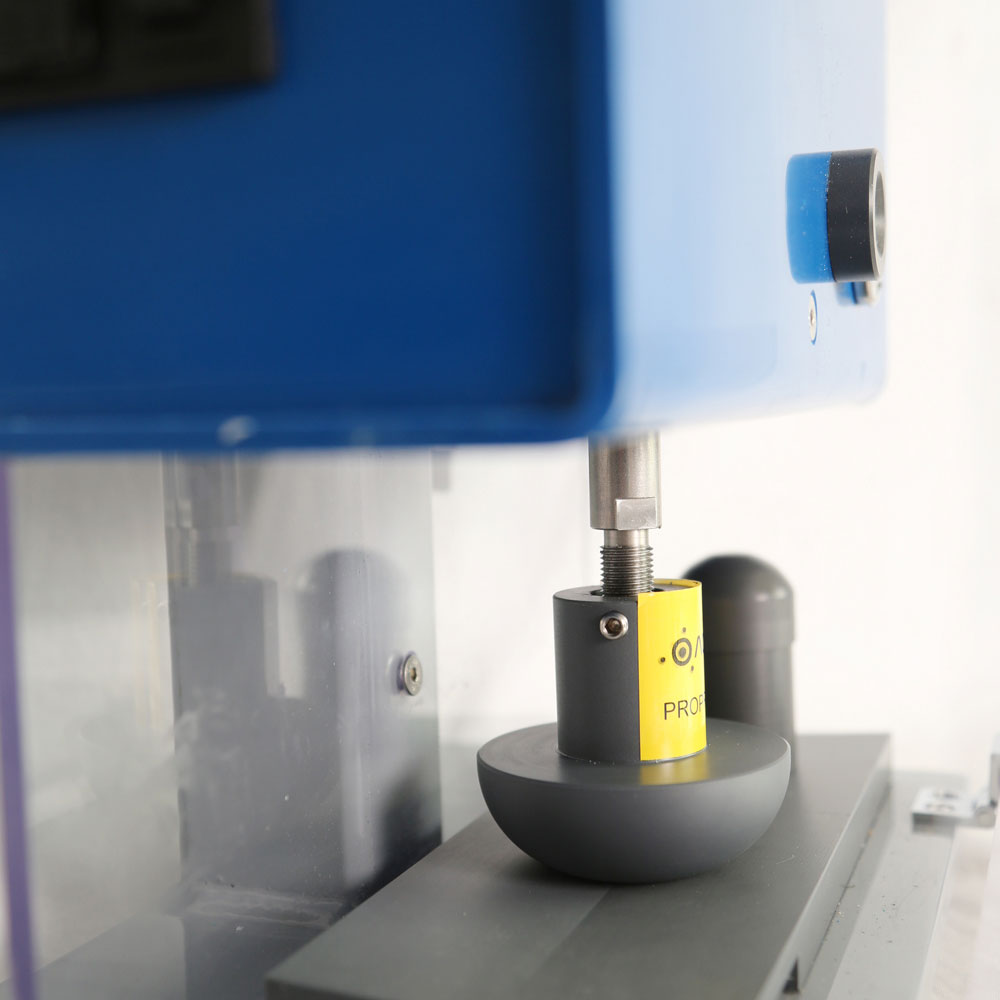

The ATS-X is the electronic weld integrity inspection tool for plastic and metalloplastic tubing, and veriies that there is no leakage under the effect of a crushing force applied to the test sample.

Like ATS, ATS-X is necessary for reliable and accurate quality control of your welds that may show defects after heat sealing.

It’s a simple, fast, affordable and completly reliable test deployed in various packaging manufacturers.

Description

As a reminder, it allows to two kinds of tests to be set up:

- Micro-leak test which increases with pressurization and causes bursting

- Burst test to determine the strength of welds.

Its electronic sensor associated with the multiple different press and positioning accessories gives it excellent repeatability and precision of measurements.

Profits

- Precise test and completely repeatable

- Precise localization of the leak

- Existing solutions for a large number of tubes and packaging

- The sample holder has an adjustable stopper, allowing testing of a wide variety of samples shapes

- Realization your tests in complete safety thanks to the transparent polycarbonate safety cover preventing its opening during the test and the start of a cycle once opened

- Transparent receptacle cleanable in case

- Traceability via a time-stamped ticket printer or data export software

- Precise electronic force sensor

Options

| Special anvils on request |

| Calibration Kit |

| Anti-marking kit |

| DataXport software |

Presser

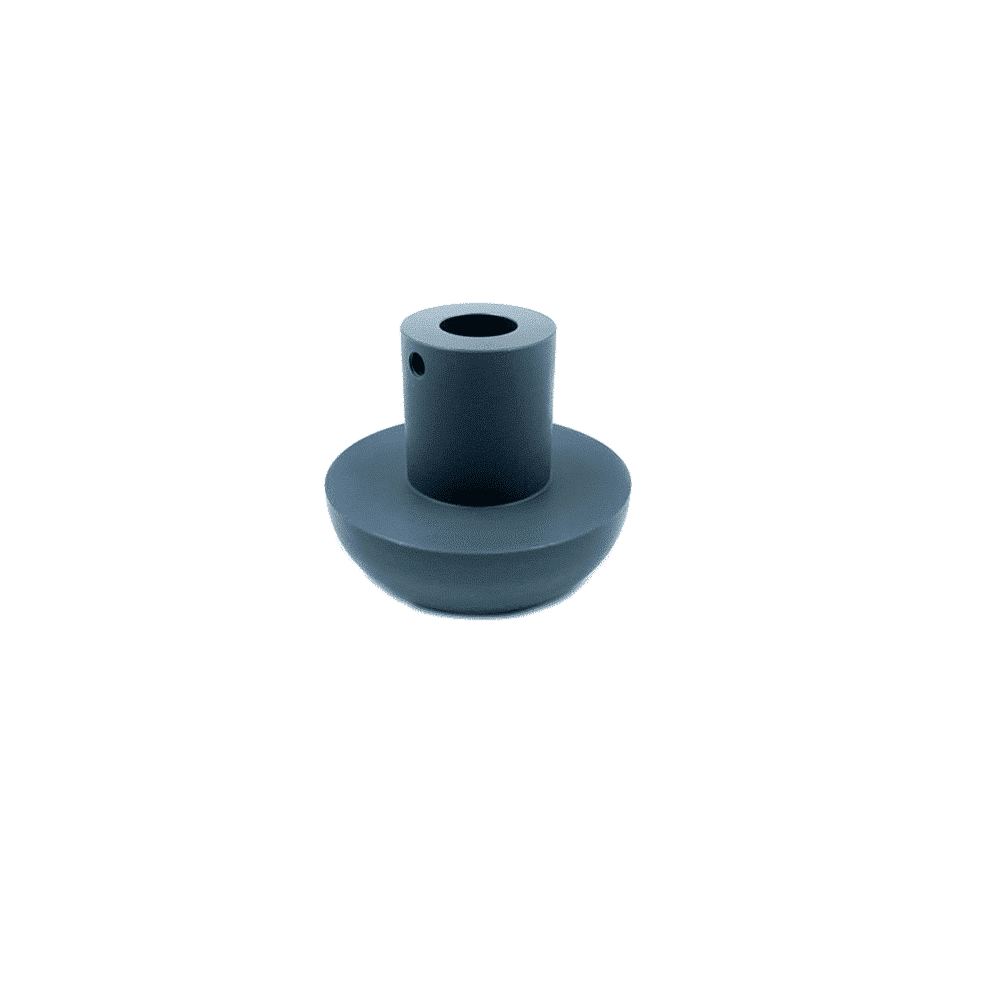

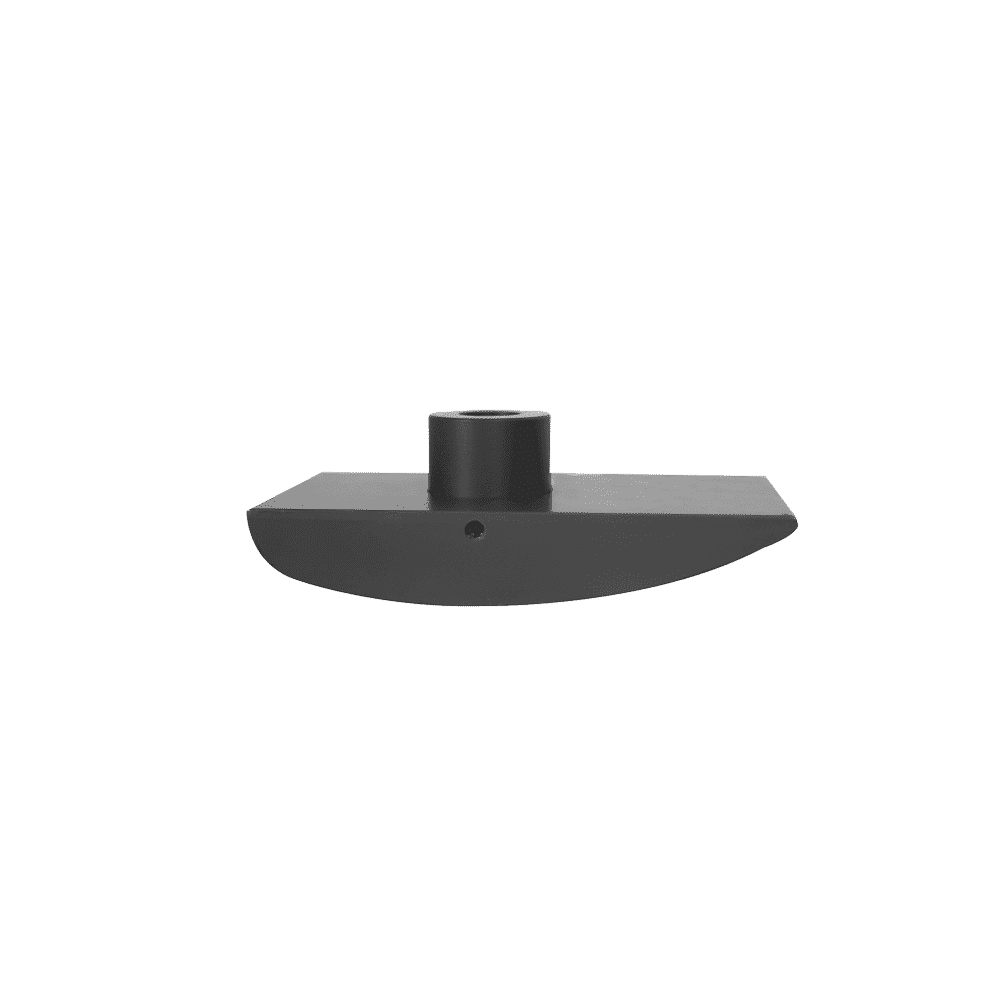

Large Mushroom Presser

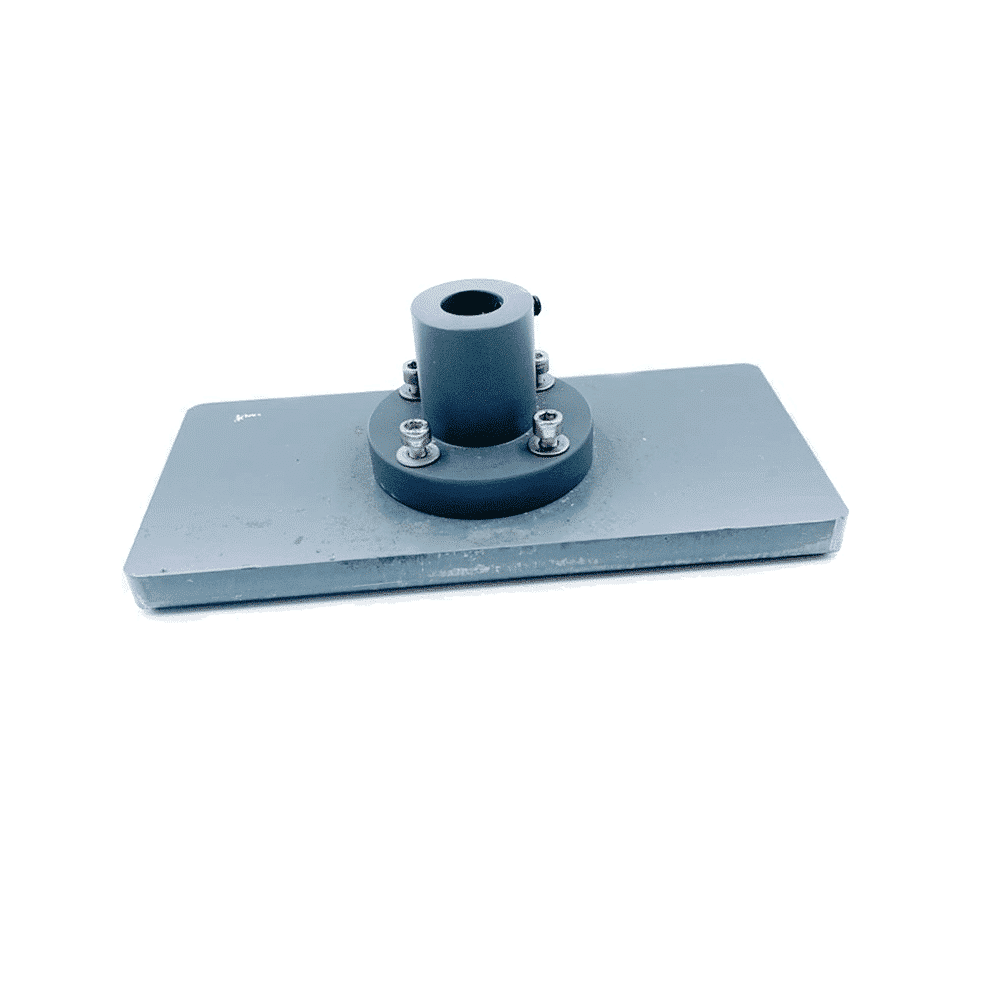

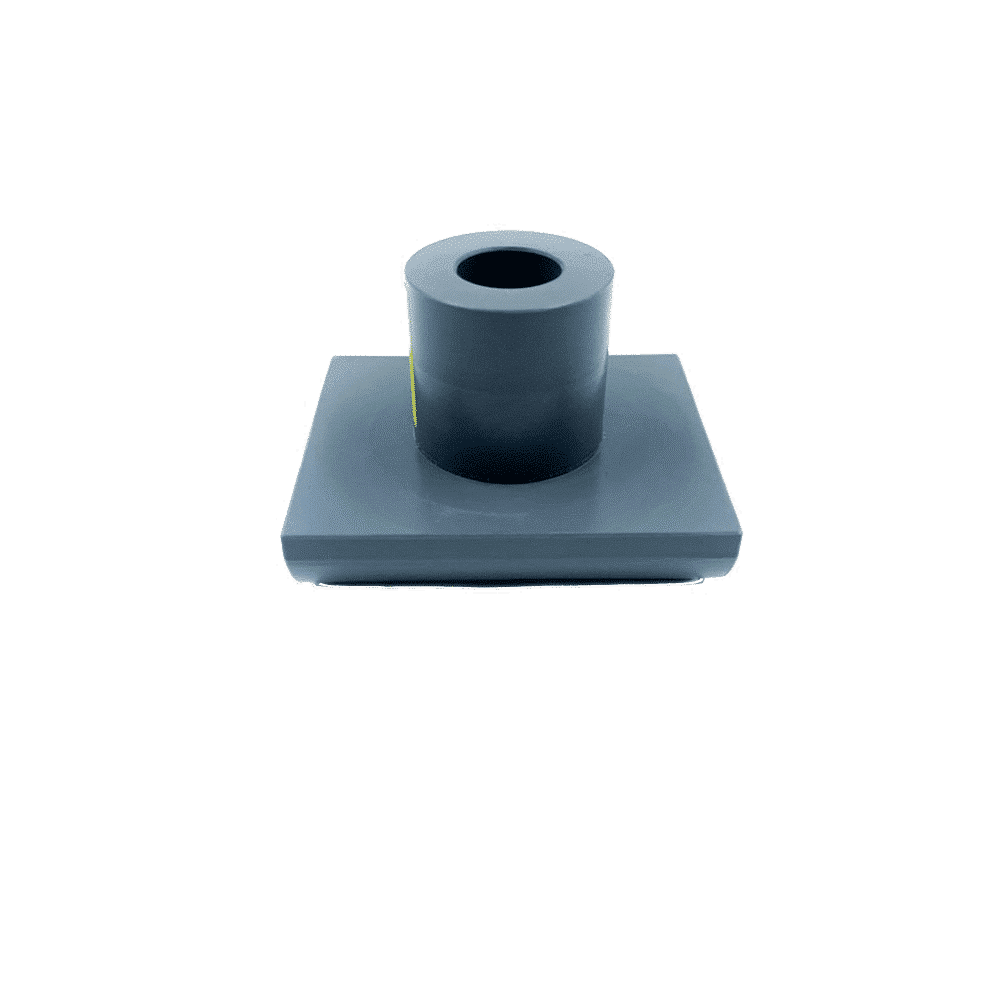

Flat Presser

Small Mushroom Presser

Mini Tube Presser

Anvil Presser

Anti-Marking Kit

Technical informations

| Crush tube | Crushes PVC tube on rigid metal frame, transparent unbreakable polycarbonate casing |

|---|---|

| Power supply | Compressed air from 0 to 10 bars |

| Autoplay | Electronic force sensor with 3 N of resolution |

| Pressure force | 50 to 1000 N |

| Time delay | Electronic timer up to 999 seconds |

| Connection power supply | Connection to the compressed air network by Rislan tube 8mm outside diameter |

| Traceability | Time-stamped ticket printer |

| Useful dimensions | W300xD280xH490 mm |

| Weight | 13 kg |