Tube crusher

Robustness and efficiency

The tube crusher (or compressiometer) is designed to guarantee reliable and precise testing of the mechanical strength of tubes, ensuring optimum quality control.

%

of satisfied customers

years of expertise

+ Tube crusher in operation

(N) Max

Our tube crusher models

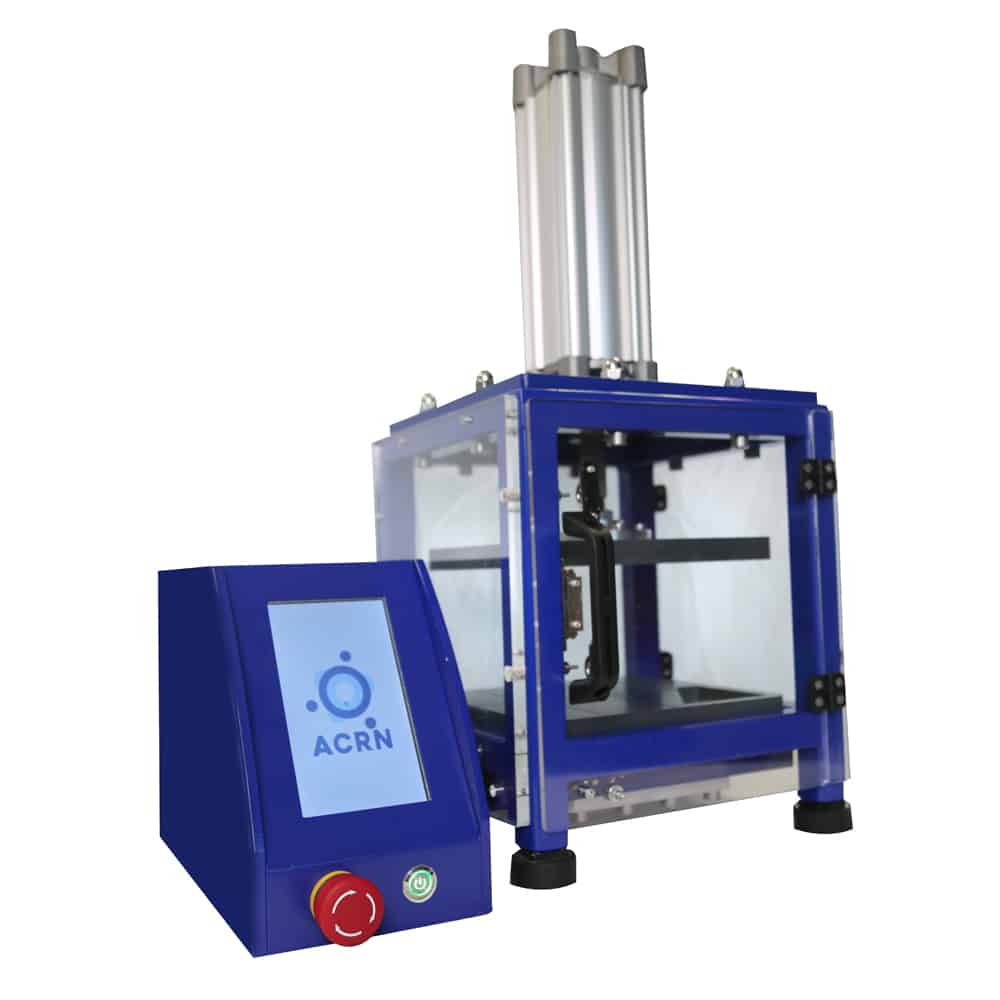

Tube crusher ATS

Test, validate, innovate with ACRN’s ATS! Designed to guarantee the reliability and strength of your assemblies, this equipment combines precision and performance for optimum quality control.

✅ Precise, repeatable measurements

✅ Automation for maximum time savings

✅ Compliance with industry standards

Choose excellence with a robust, efficient tool for securing your production.

Tube Crusher ATS 3 Heads

Tube Crusher ATS 3 Heads is the ideal solution for testing several points of an assembly simultaneously, with absolute precision.is the ideal solution for testing several points of an assembly simultaneously, with absolute precision. Designed for demanding industrial environments, it offers speed, reliability and repeatability in every test.

✅ Multi-point testing in a single operation

✅ Save time and reduce production cycles

✅ Maximum reliability to ensure compliance

Boost your productivity and secure your quality with Tube Crusher ATS 3 Heads.

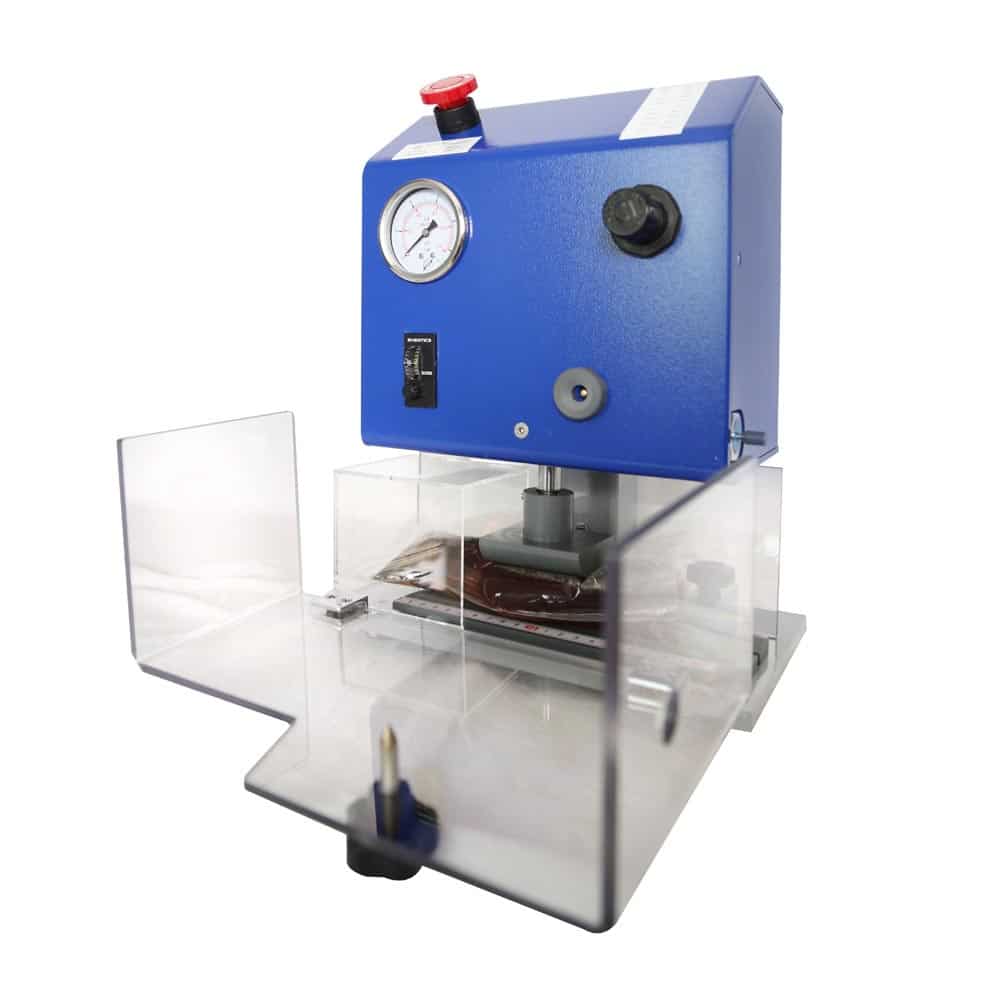

PouchTube

Designed to accurately assess the strength of flexible tubes, the PouchTube is the essential tool for demanding industrialists. Thanks to its advanced technology, it guarantees reliable, rapid and repeatable testing for optimum quality control.

✅ Precise measurement of pressure and deformation

✅ Suitable for soft and flexible tubes

✅ Optimize test cycles for maximum time savings

Ensure the conformity and reliability of your products with the PouchTube.

Comparative table ACRN tube crusher

Options and Services

Printer

Print results

Anti marking kit

In this context, the non-destructive press does not degrade the envelope of the tested samples.

Calibration Kit

Measures the internal pressure of a tube when crushed by a tube crusher.

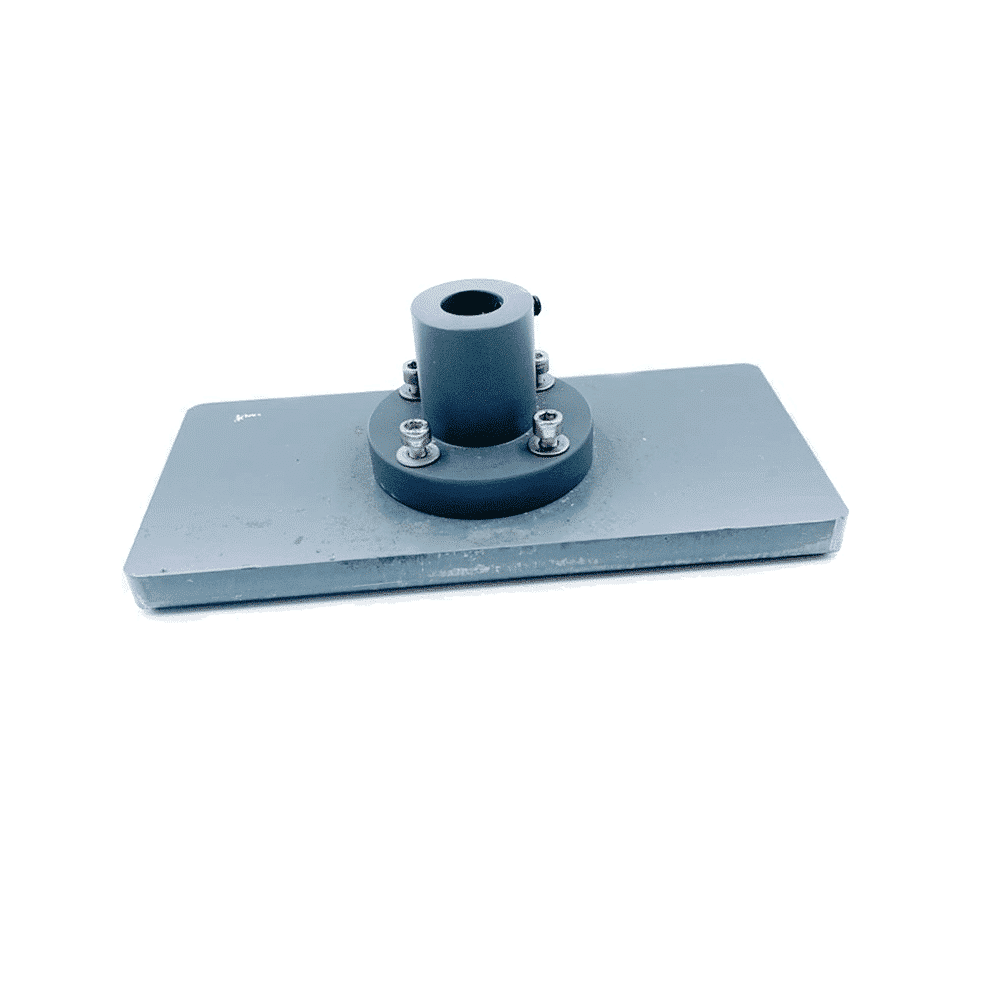

Flat presser

Several formats for your different bags

CFR 21

Compliance with regulatory standards for the pharmaceutical industry

On–site installation

Full installation and commissioning service

User training

Comprehensive training on equipment use

Qualification

Equipment calibration and qualification service

Any tests to be carried out on doypacks?

The CompressPack is used to check the weld strength of plastic or metal packaging such as doypacks, doypack refills, pouches, bags and tubes directly on the production line or in the laboratory.

It can be used in addition to the ATS tube seal tester.

Why test your weld ?

During the heatsealing process, defects in the weld can appear dur to the temperature of the electrodes and the presence of impurities.

A crush test is used to check the integrity of your sample’s weld, and therefore the absence of leaks or micro-leaks. This test is indispensable for validating the correct welding of your samples.

Ce que nos clients

Contact us

Need advice or a personalized quote?

At ACRN, we know that every application requires precise, customized solutions. Our Tube Crushers, whether new or adapted to your existing equipment, are designed to meet your quality and performance requirements.

✅Why choose an ACRN Tube Crusher?

- Unrivalled precision for reliable measurements.

- Customized options to suit your specific needs.

- Technical support from experts in the field.

Please fill in the form opposite:

- Ask your questions.

- Ask for a quote.

- Seek expert advice.

📞 An urgent question? Contact us directly at 0232808140 or contact@acrn.fr.

We’re here to help you make your projects a success!

Frequently asked questions about the Tube Crusher

What is the Tube Crusher and what is it used for?

The Tube Crusher is a device designed to test the integrity of welds on tubes, pouches and bags. It is essential for packaging quality control, guaranteeing flawless welds and preventing leaks.

What are some of the other names used for a Tube Crusher?

There are several names for this type of device. Compressiometer and Jacomex are the most common.

What types of packaging can be tested with these devices?

They are suitable for testing a variety of packaging materials, including plastic and metal tubes, pouches, bags and doypacks.

In which sectors are they used?

PouchTube, ATS and Tube Crusher ATS 3 Heads are mainly used in the pharmaceutical, cosmetics, food processing and medical industries.

What maintenance is required for these devices?

They are designed for durability and minimal maintenance, reducing costs and production downtime.

Are these devices suitable for use on production lines?

Yes, their ergonomic, robust design makes them easy to integrate into production lines for real-time quality control.

What are the main features of the PouchTube Tester?

The PouchTube Tester can be used to check the performance of tubes, pouches and other refills directly on the production line or in the laboratory. It offers fast, reliable and repeatable tests to check weld integrity.

Can several packs be tested simultaneously with these devices?

The Tube Crusher ATS 3 Heads multi-tube tester allows up to three tubes to be tested simultaneously, increasing quality control efficiency.