Tube Crush ATS 3

Test several samples at the same time

The ATS 3 heads is the tool to control the weld strength of plastic and metal-plastic pipes directly on the production line or in the laboratory.

The weld integrity is verified by the absence of leakage under the effect of a crushing force applied to the sample to be tested.

It’s a simple, fast, affordable and completely reliable test deployed in various packaging manufacturers.

Description

Like the ATS, the ATS 3 is essential for reliable quality control of your welds which may show defects after heat sealing. Theses three different compartments give you the simultaneous control of three similar samples, or even different ones thanks in particular to an independent control of the pressure if each manometer. This is very useful in the event of a high frequency of checks or in case of a significant spot check following a complaince problem. This is very useful in the event of a high frequency of checks or in case of a significant spot check following a complaince problem.

Thanks to it’s numerous press and it’s intuitive design, it allows an excellent repeatability of measurements.

As a reminder, it allows to two kinds of tests to be set up:

- Micro-leak test which increases with pressurization and causes bursting

- Burst test to determine the strength of welds.

Profits

- Fully pneumatic, low maintenance

- Depression adjustment specific to each pressure gauge

- Easy to use

- Realization your tests in complete safety thanks to the transparent polycarbonate safety cover preventing its opening during the test and the start of a cycle once opened

- Positionning rules fot simultaneous testing of 3 same samples

- Delivered with 2 press of different size according to the tube diameter

Options

| Special anvils on request |

| Calibration Kit |

| Anti-marking kit |

Presser

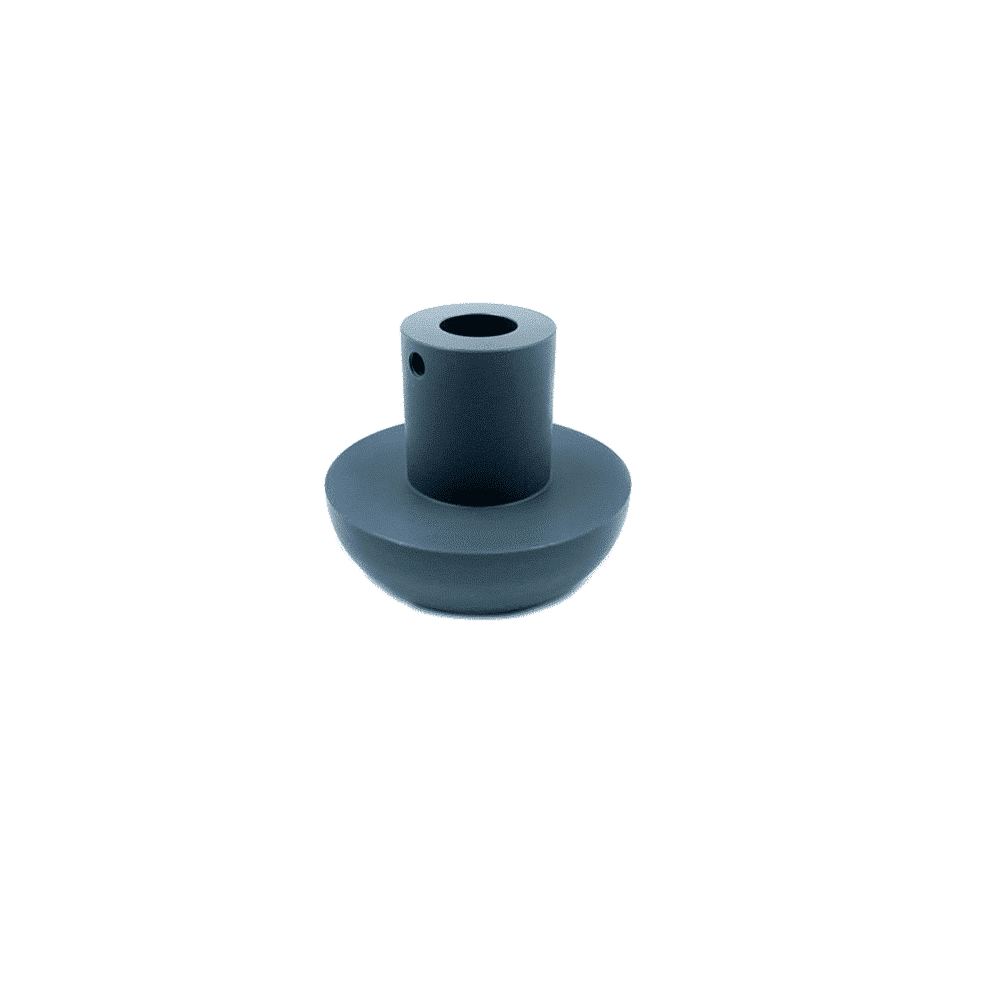

Large Mushroom Presser

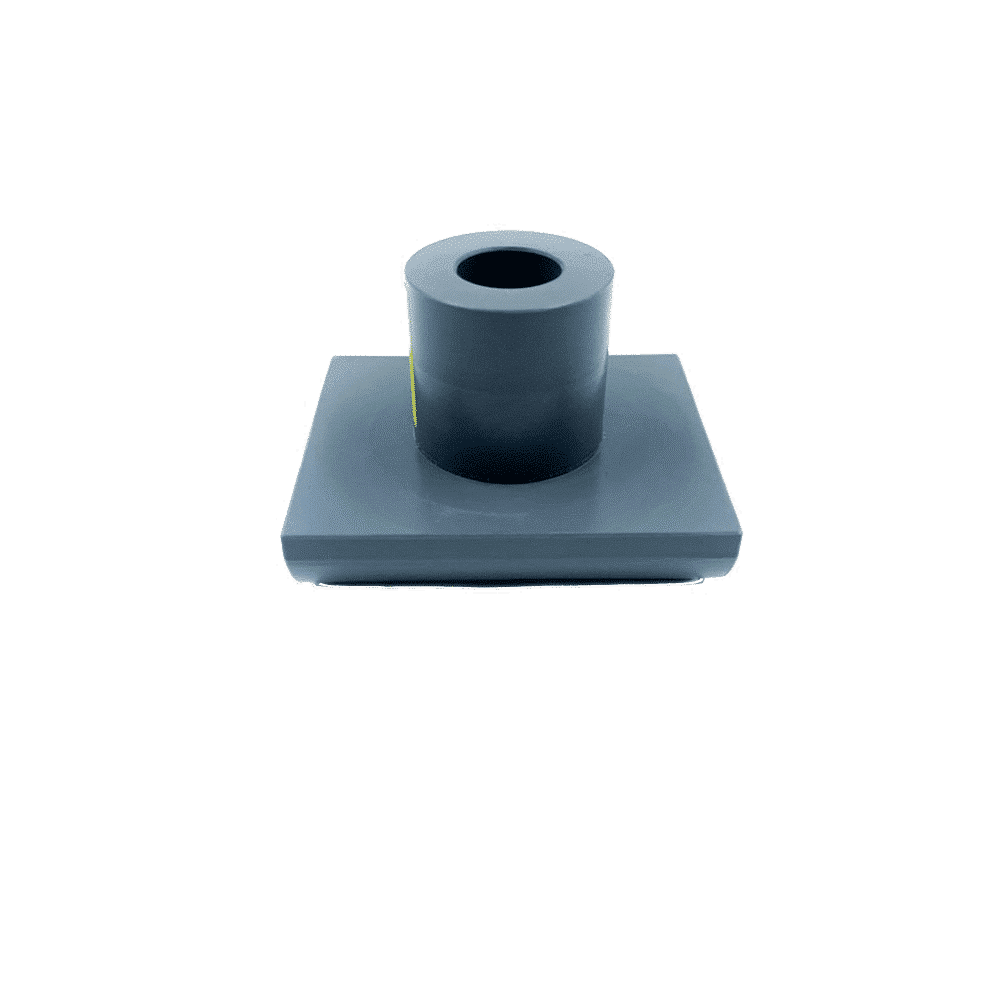

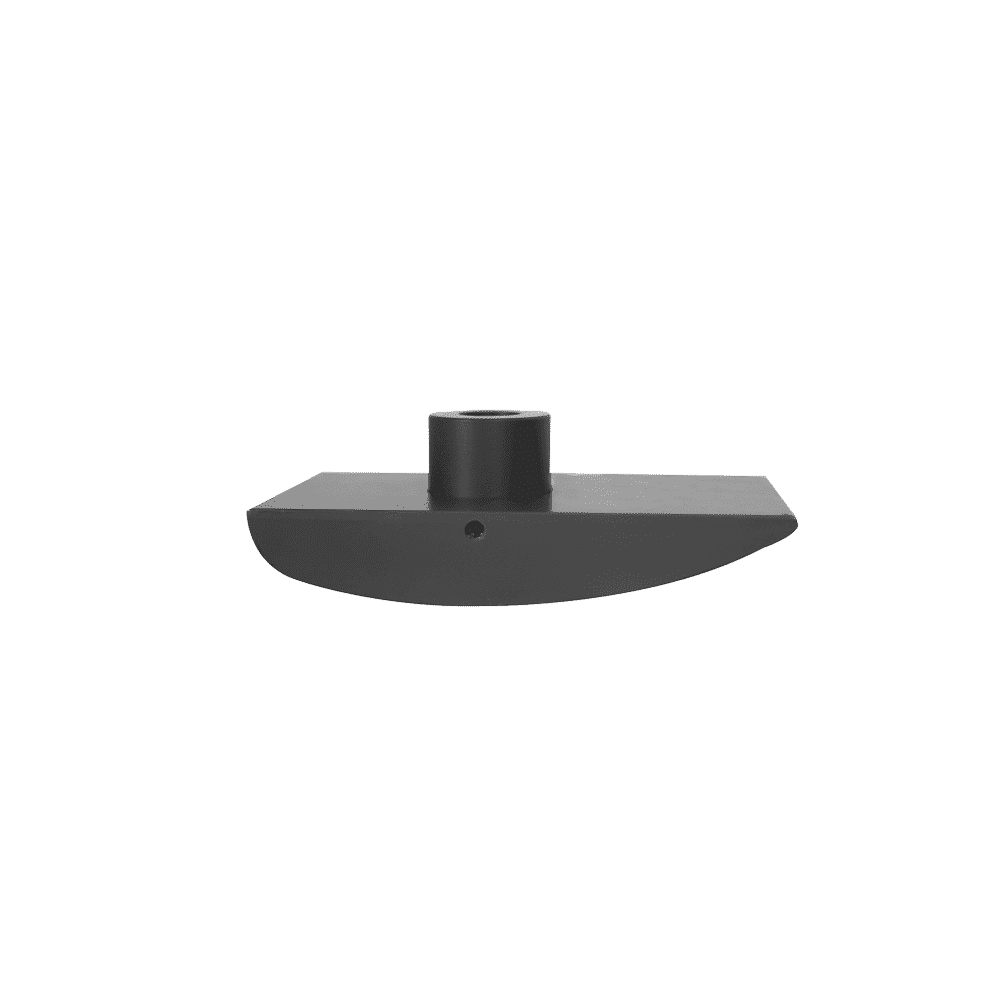

Flat Presser

Small Mushroom Presser

Mini Tube Presser

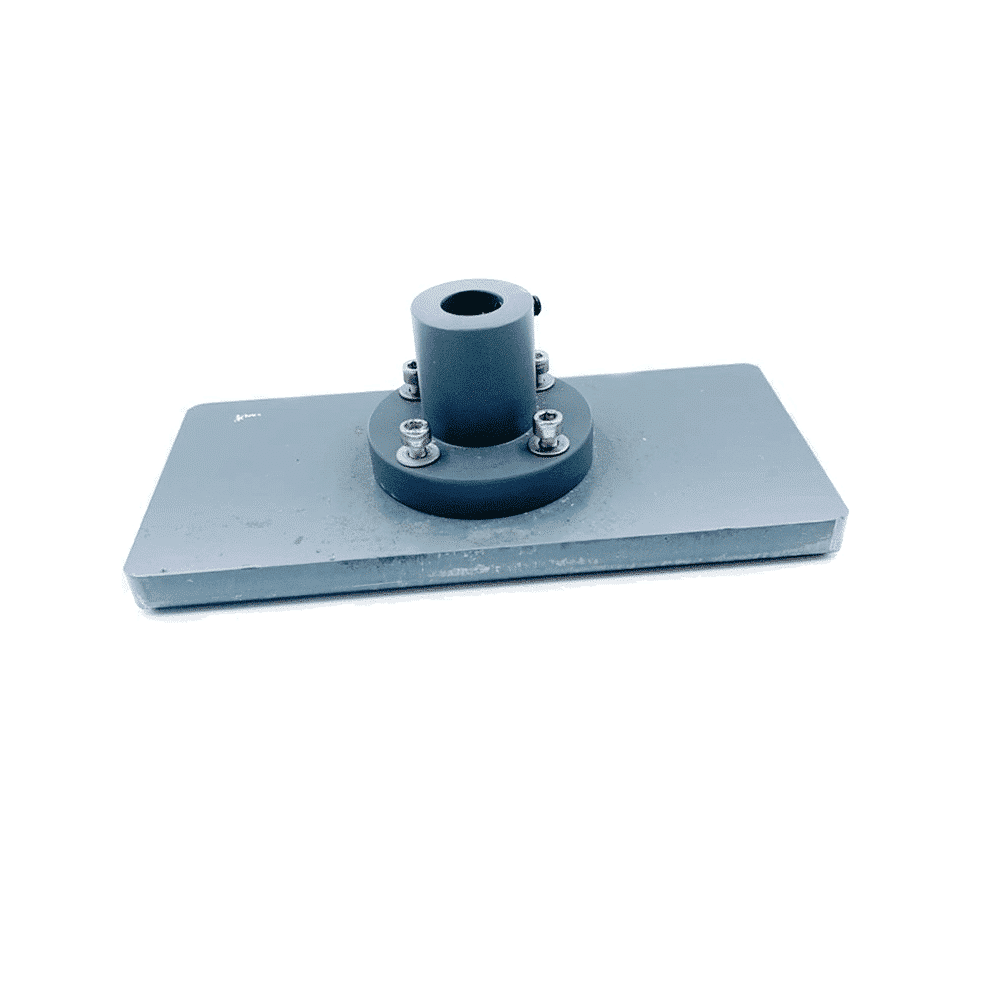

Anvil Presser

Anti-Marking Kit

Informations complémentaires

| Crush tube | Crushes PVC tube on rigid metal frame, transparent unbreakable polycarbonate casing |

|---|---|

| Power supply | Compressed air from 0 to 10 bars |

| Reading | Graduated manomaters from 0 to 10 bars |

| Pressure force | From 50 to 1 000 N |

| Pressure adjustment | Adjustment dial pressure regulator |

| Timer | Adjustable from 0 to 30 secondes |

| Power supply connection | Connection to the compressed air network by means of a Rislan tube with an external diameter of 8mm |

| Useful dimensions | L520xD310xH400 mm |

| Weight | 30 kg |