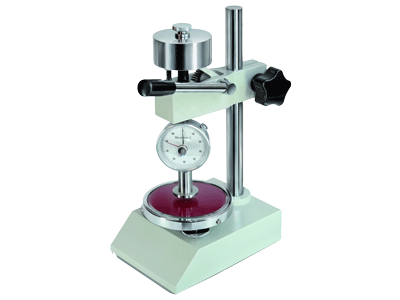

Shore hardness tester with indicator needle

Simply test your plastics

This hardness tester makes measuring the hardness of plastics simple and straightforward.

A metal tip of a defined shape is pressed against the sample by a spring. The depth of the impression is then used to determine the hardness or softness of the material.

This procedure is described in DIN ISO 7619-1:2012.

This shore hardness tester is also available in a digital version.

Description

The typical application of this handy shore hardness tester is the measurement of the depth of intrusion.

It is particularly recommended for internal comparative measurements. Standard calibrations are often not possible due to the very narrow tolerances.

- Shore A:for rubber, elastomer, neoprene, silicone, vinyl, soft art plastic, felt, leather and similar materials

- Shore D: plastic, resin, resopal, epoxy, plexiglass, etc.

- Shore A0:mosses, sponges

The MAX mode captures the maximum value using the drag pointer.

Options

Shore calibration plates for checking and calibrating Shore hardness testers. The accuracy of measurement increases considerably through regular balancing.

- 7 Hardness reference blocks for Shore A, tolerance up to ± 2HA

- 3 hardness reference blocks for Shore D, tolerance up to ± 2HD

| Type of hardness | Measuring range | Autoplay | |

| Model 1 | Shore A | 100 HA | 1,0 HA |

| Model 2 | Shore A0 | 100 HA0 | 1,0 HA0 |

| Model 3 | Shore D | 100 HD | 1,0 HD |

Compatible with a test bench

The handy shore hardness tester with indicator needle can be installed on a lever test stand. It is suitable for shore hardness testing of leather, plastics, or other materials.

A glass plate provides high measuring accuracy by the stronger hardness of the glass base plate. The robust design allows precise measuring movements. This test stand also contains a levelling attachment for exact levelling of the base plate, e.g. for inhomogeneous test objects.

Informations complémentaires

| Accuracy | 3% of max |

|---|---|

| Dimensions (LxPxH) | 60 x 25 x 115 mm |

| Net weight approx. | 0,16 kg |

| Screws for test bench mounting | M7 fine thread |

| Minimum sample material thickness | 4 mm |