CTEX Leak test box

Robuste and versatile model

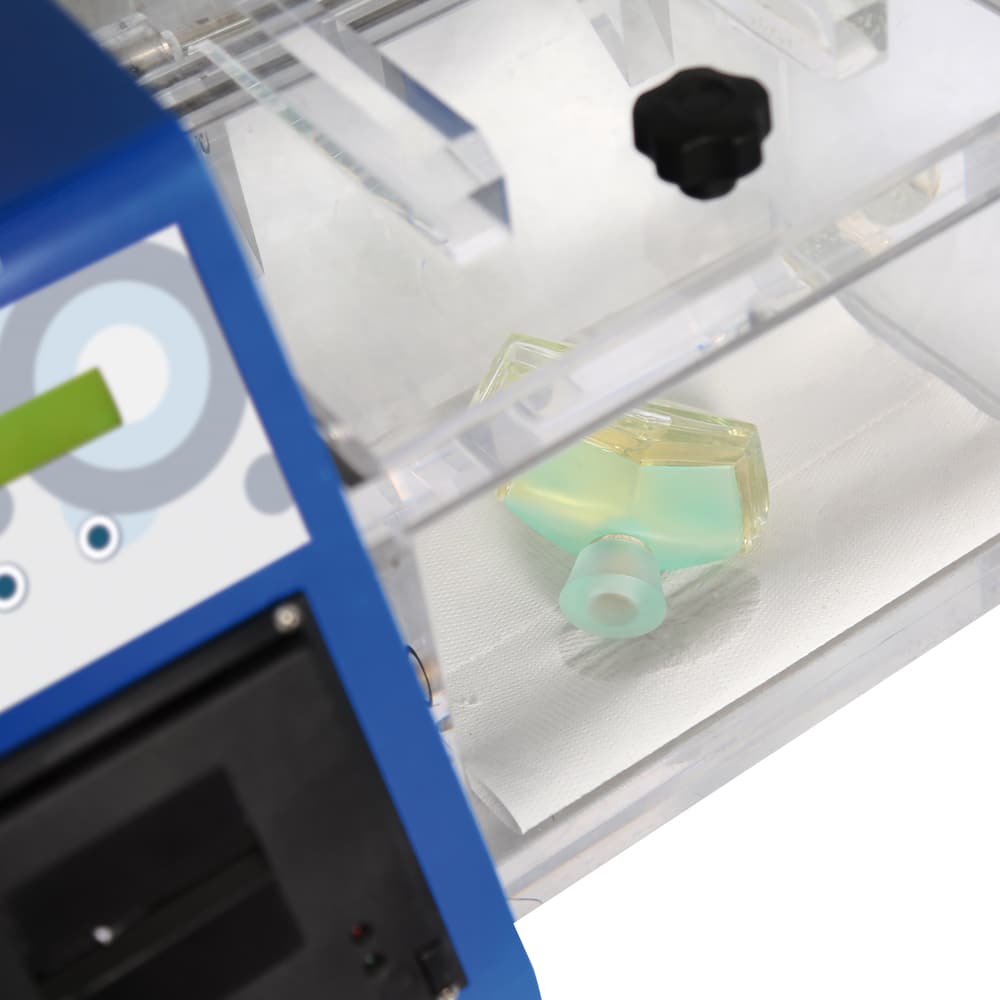

Its allow to test tightness of packaging containingliquid or semi-viscous products, by depression directly at the edge of the production line with full visibility, thanks to its plexiglass design.

Just lay your sample down toimmerse your cap. Using blotting paper, for example, allows you to see if any product has leaked from the sample during the test.

This model is available with a vacuum pump system for vacuuming.

Description

Benefits

- Fast, ergonomic and easy to use

- Visual reading

- Reliable and economical

- Adapted to the production envrionment / Robust

- Test on receipt of raw materials, in production, before shipment

- Pressure sensor in the control box

- Traceability by a printed time-stamped ticket containing the test information or by data export software

Technical information

| Box | Transparent PMMA chamber on hinge |

| Range of measurements and accuracy | From -0.1 to -0.85 Bar as standard. Accuracy + / -2 % Fully controlled by a microprocessor card |

| Useful dimensions | It depends on the size of box. |

| Reading the depression | Digital display : ergonomic menu with only 3 keys. |

| Units | Bar, Psi |

| Power supply | – On compressed air 7 bar / – Vacuum pump |

| Weight | Depends box defined |

| Thickness | 20, 25 or 30 mm depending on the RDM study |

| Depression adjustment | Solenoid valve |

| Printing | Printer embedded tickets for ticket stamped |

| Depression time | Adjustable delay from 0 to 4 000 s |

| Principle of the test | Visual |

| Temperature | From 0 to 40°C |

| Standards | IATA, ASTM D6653, ASTM D4991, ASTM D5094, ASTM D4169, EN 14401, DIN55528 (Part 1, 2, 3, 4, 5) |

| Programming | 8 independent programs (time/ depression) that can be liked together |

Options

| Decrease in depression time (vacuum pump, more powerful venturi) |

| Replacement of the factory compressed air connection system with a vacuum pump (see technical sheet) |

| Model without printer |

| Software for acquisition data bit by bit towards any PC software |

| Air drain valve for easy return to PA. |

| Pneumatic safety cylinder |

| Vacuum pump replacing compressed air |

| Custom interior design |

Delivered with:

A calibration certificate LNE / COFRAC