Torque Measurement

Torque measurement

Simply measure the torque under industrial screwing machines

Measuring the unscrewing torque of packaged sample caps can reach limitations.

Checking the tightening torque, verified directly under the screwdriver, is useful in the following cases:

- Know the real value of the static torque applied to the products to be screwed

- Check the repeatability of the screwing machines

- Provide additional information to diagnose the various problems of your packaged products (sealing, screwing, etc..)

- Check that the unscrewing torque problems are not related to the machine

- Collect preventive maintenance and process control data

Data sheet Torque controller under screwdriver

Description

A screwdriver torque controller is an essential tool in industries where precise tightening is crucial. It measures, controls and checks the torque applied by an industrial screwdriver. This device guarantees tightening conformity, prevents over- or under-tightening, and ensures consistent quality in your assembly processes.

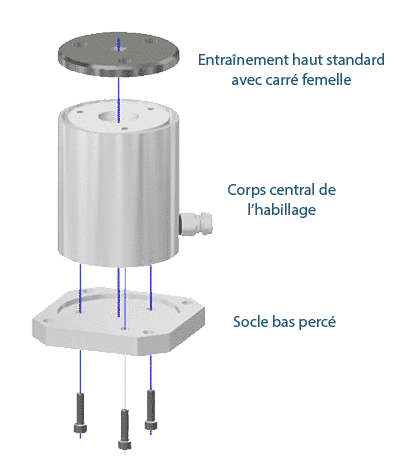

System description

Measurement console XA-m

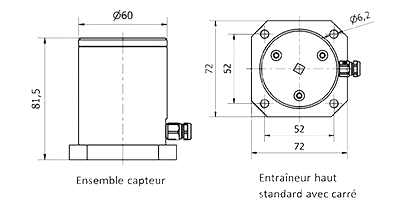

Embedded sensor with a capacity from 0.5 to 25 N.m

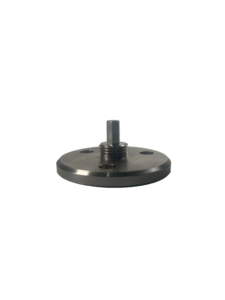

Upper standard drive with female

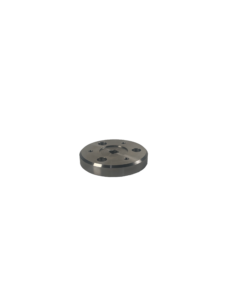

Base with hole drilling

Central body of the sensor casing

Dimensions for female square:

Possible adaptations for the top drive of the srewing machine:

-Other dimension of squares

-End caps

-Dummy caps

Possible adaptations fot the plinth:

Customized base for adaptation of buckets or specific dimensions.

Options and accessories

| Printer |

| Extended wires |

| Additional sensors |

| Dummy caps |

| Drive adapters |

Informations complémentaires

| Type of sensor | Self-stabilizing reinforced static torque sensor |

|---|---|

| Capacity (N.m) | 0.5/ 1/ 3/ 5/ 10/ 25 |

| Units | N.m / lbf.inch / N.cm / Kgf.cm |

| Dimensions | See outline below |

| Weight (sensor kit) | 700g |

| Sampling rate | 5 000 Hz |

| Accuracy | 0.1 % FS |

| Resolution | 0.001 N.m |

| Autodiagnostic | Sensor offset indicator |

| Safe overload | 150 % |

| Standard drive | Female square ¼’’ |

| Power supply | 220 V / 50-60 Hz |