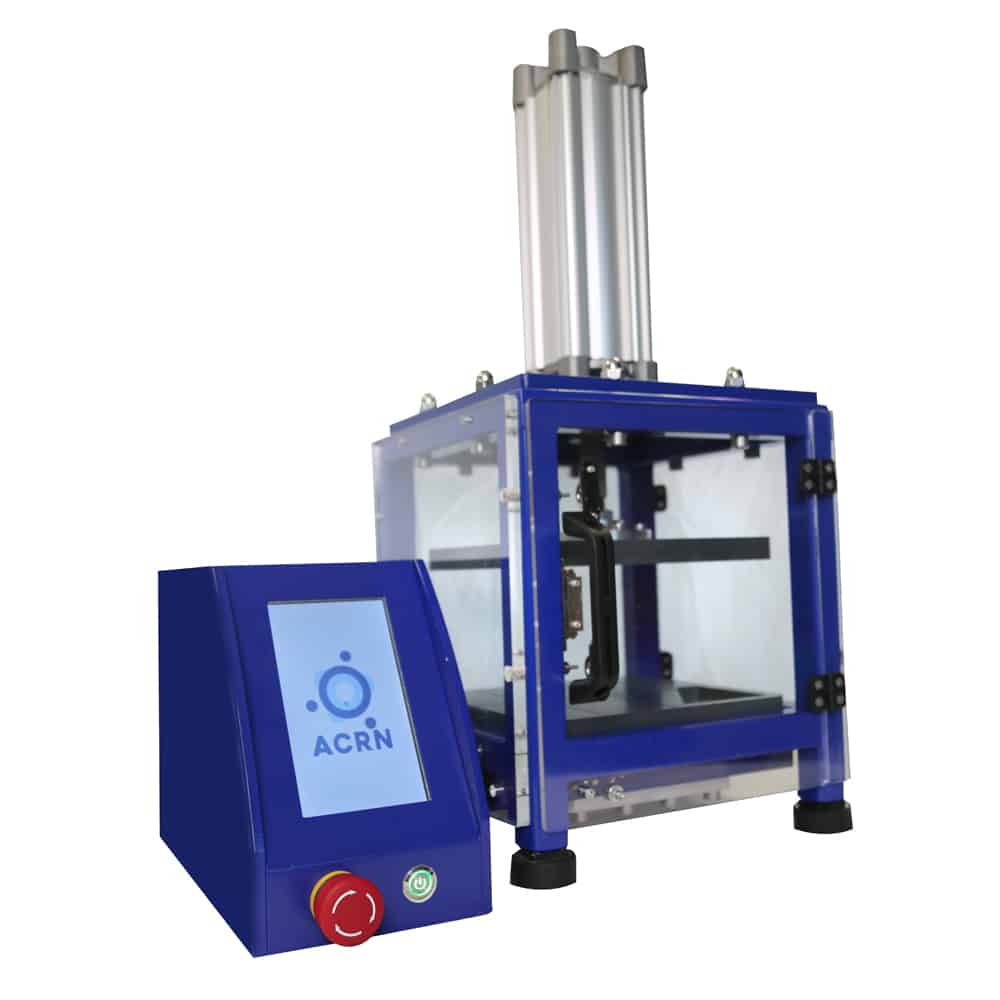

Bag and doypack weld tester CompressPack

Test your packaging seals in a few seconds

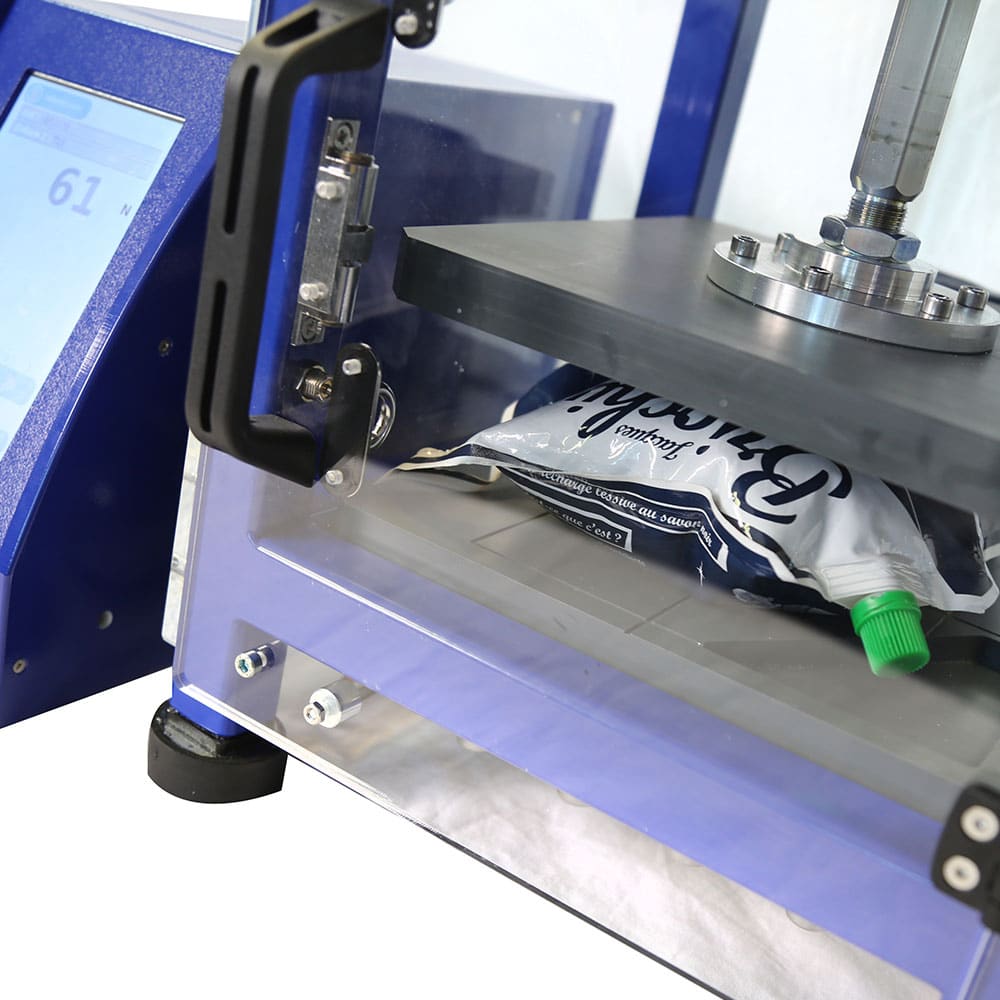

The CompressPack is used to check the weld strength of plastic or metal packaging such as doypacks, doypack refills, pouches, bags and tubes directly on the production line or in the laboratory.

It can be used in addition to the ATS tube seal tester.

Why test your weld ? During the heat sealing process, defects in the weld can appear due to the temperature of the electrodes and the presence of impurities.

The implementation of a crush test allows to check the integrity of the weld of your sample, and thus the absence of leakage or microleakage. This test is essential to validate the good welding of your sample.

Description

Benefits of CompressPack

– Designed for many types of tests (fatigue test, stress test, burst test, leak test, etc.)

– Adapted to production environments thanks to innovative and intuitive design

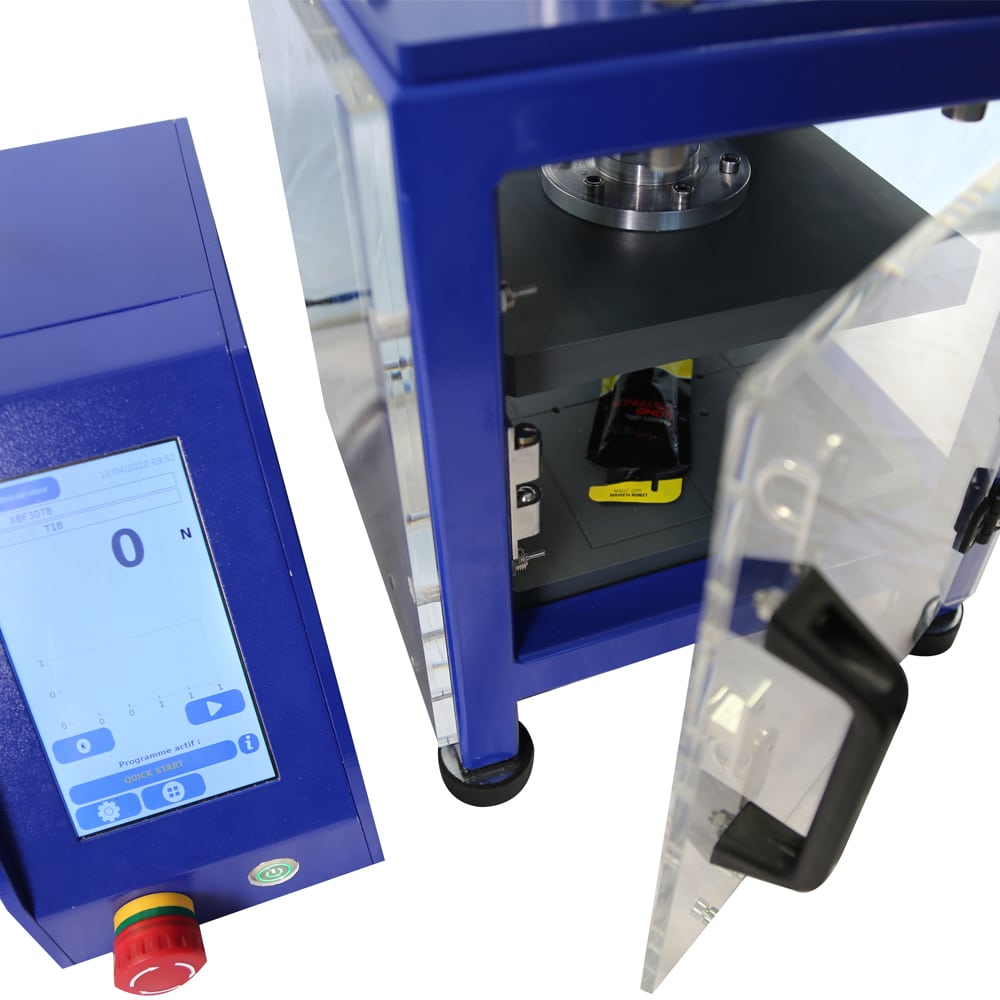

– Traceability and validation of test conformity, Management of batch numbers; User identification with access limits

– Quickly interchangeable pressers according to the type of packaging

– Improved cleanability thanks to its multi-opening door or the use of a pratical retention tray for development tests

– Data integrity : advanced result analysis/export (USB/ TCPIP)

– Self-diagnosis capability (sensor drift,…)

– Simultaneous depression graph of the test

– Detachable control box for easy after-sales service, but also portable for hostile or congested environments.

Different tests can be performed:

Resistance test

Perfom a test on your packaging by the cycle function to test the integrity of your packaging.

Cyclic test

Carry out a stress test with raising and lowering of the pneumatic cylinder

Manual test / internal pressure

Conduct step-by-step test to facilitate internal measurement for a reliable and accurate test.

Burst test

Carry out a test with detection of the bursting threshold.

Customized test

The compresspack can integrate a program developed specifically for the customer (e.g.: internal test protocol of a manufacturer that can be deployed on all production sites by source file on USB key).

Staircase test

Carry out a development/qualification test to determine the compliance values of a product.

Types of packaging:

Flexible, semi-rigid and rigid packaging

Technical specifications according to the support force:

| L75 | L190 | L300 | L1600 | L3000 | S190 | S300 | S1600 | |

| Min strength (daN)

Min pressure (bar) |

2

0,2 |

6

0,2 |

10

0,2 |

50

0,2 |

100

0,2 |

6

0,2 |

10

0,2 |

50

0,2 |

| Standard strength (daN)

Standard pressure (bar) |

75

6 |

190

6 |

300

6 |

1600

6 |

3000

6 |

190

6 |

300

6 |

1600

6 |

| Max strength (daN)

Max pressure (bar) |

100

8 |

250

8 |

400

8 |

2100

8 |

4000

8 |

250

8 |

400

8 |

2100

8 |

| External dimensions (mm) (W*D*H) | 570*460*650 | 570*460*650 | 570*460*693 | 570*460*727 | 546*398*710 | 380*460*449 | 380*460*492 | 380*460*526 |

| Maximum sample size (mm) (W*D*H) | 340*270*185 | 340*270*180 | 340*270*160 | 340*270*120 | 340*270*110 | 230*132*185 | 230*132*165 | 230*132*125 |

Informations complémentaires

| Energy | Compressed air resolution 0 to 6 bar |

|---|---|

| Control box dimensions | W160 x D350 x H240 mm |

| Frame size with cylinder | W346 x D460 mm (W)/ |

| Useful test dimensions | W340 x D270 mm (L) / W230 x D132 mm (S) |

| Power supply | 110Vdc 230Vdc, 50 hz/60hz |

| Compressed air supply | Between 0 to 8 Bars |

| Display | 7" capacitive touch |

| Accuracy | 1 Newton |

| Max. sampling frequency | 1500 hz |

| Air filter | 5 μm |

| IP Classification | IP54 |

| Operation temperature | Between 0° and 40°C |

| Noise level | < 25 dB |

| Power consumption | <0,1kW |

| Compressed air consumption | GV15 : 100NL/min |

| Connection to the compressed air network | ISO B6 Male and ⌀8mm external quick coupling |

| Communication | Printer, RS232, TCP-IP, Exports CSV, XML, USB, open communication protocol |