Dry leak testing

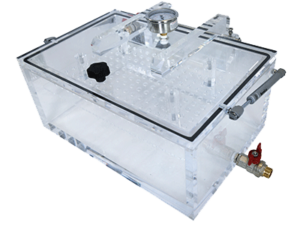

It is used to test the tightness of packaging containing liquid or semi-viscous products, by depression, directly on the production line with a total visibility, thanks to its plexiglass design.

Just lay down your sample to immerse your cap. The use of blotting paper by example, allows you to see if the product has leaked from the sample during the test.

Suitable for production environments, it has a fully pneumatic system, capable of creating a vacuum, and a compressed air control valve to limit the incoming flow.

If the company can’t provide this kind of supply, there are models called CTS and CTEX, which can work with vacuum pumps up to -920 mbar.

Compatible with standards

-EN-14401 : Methods for testing the closure efficiency of rigid plastic containers

–ASTM D6653 : Determining the effects of high altitude on packaging systems by vacuum methode

Showing all 4 results

You need to choose the most effective solution for your needs, for that you will have to choose among our three control boxes and a box of adapted size.

Choice of the box

CTS

The manual dry seal box that can operate with compressed air. or a vacuum pump..

The CTS is a entirely pneumatic vacuum bell model requiring no operator maintenance.

This sealing box is intuitive and easy to use thanks to its three-way valve. The simple and quick reading of the result due to the needle manometer and the transparency of the box.

Le CTE

The 100% pneumatic dry seal box operating solely on compressed air.

This model is advantageous because its test is fast, ergonomic and easy to use. It is possible to control the vacuum with a pressure reducer but it is also possible to control the timing of the test. The operator can stop the test at any time by pressing the emergency stop button on the front of the device.

CTEX

The electropneumatic dry leak test chamber, can operate with a vacuum pump or compressed air. It will provide you with very accurate data thanks to the use of a precise pressure sensor (+ / – 3 mbar) located in the control box.

Robust model adapted to the production environment. Traceability by a printed time-stamped ticket containing the test information or by a data export software.

Value of vacuum and time entirely configurable in different programs that can be cycled for complex test simulations.

Choice of housing

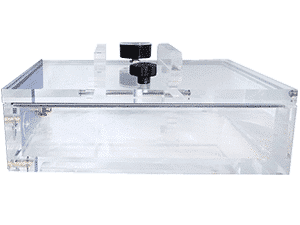

Box with lid

It is possible to choose boxes with a 100% transparent cover and a possible interior design.

We can also add creepers for handling assistance and holding up.

Several box sizes exist with weights ranging from 7 kg to 28.5 kg and capacity volumes between 7,5L and 60L.

Door Box

There are also door pedestals with removable shelves and different arrangements possible.

For this type of box there are 3 models between 25 Kg and 60 Kg and with capacities between 36L and 112,5L.

Our different sizes of standard boxes

| Useful box dimensions (mm)* | Name of the model | Trunk | Cabinet | Water immersion | Methylene blue immersion | Cart on request | Support cylinder |

| L300xD300xH400 | A1 | X | X | ||||

| L400xD400xH400 | A2 | X | X | ||||

| L500xD450xH500 | A3 | X | X | ||||

| L250xD200xH150 | C1 | X | X | X | |||

| L350xD250xH80 | C2 | X | |||||

| L350xD250xH150 | C3 | X | X | X | |||

| L350xD250xH250 | C4 | X | X | X | X | ||

| L450xD350xH100 | C5 | X | X | X | |||

| L450xD350xH150 | C6 | X | X | X | X | X | |

| L450xD350xH200 | C7 | X | X | X | X | X | |

| L450xD350xH300 | C8 | X | X | X | X | X | |

| L500xD400xH100 | C9 | X | X | X | |||

| L500xD400xH200 | C10 | X | X | X | X | X | |

| L500xD400xH300 | C11 | X | X | X | X | X |

*Custom sizes possibles up to 0,8 m3