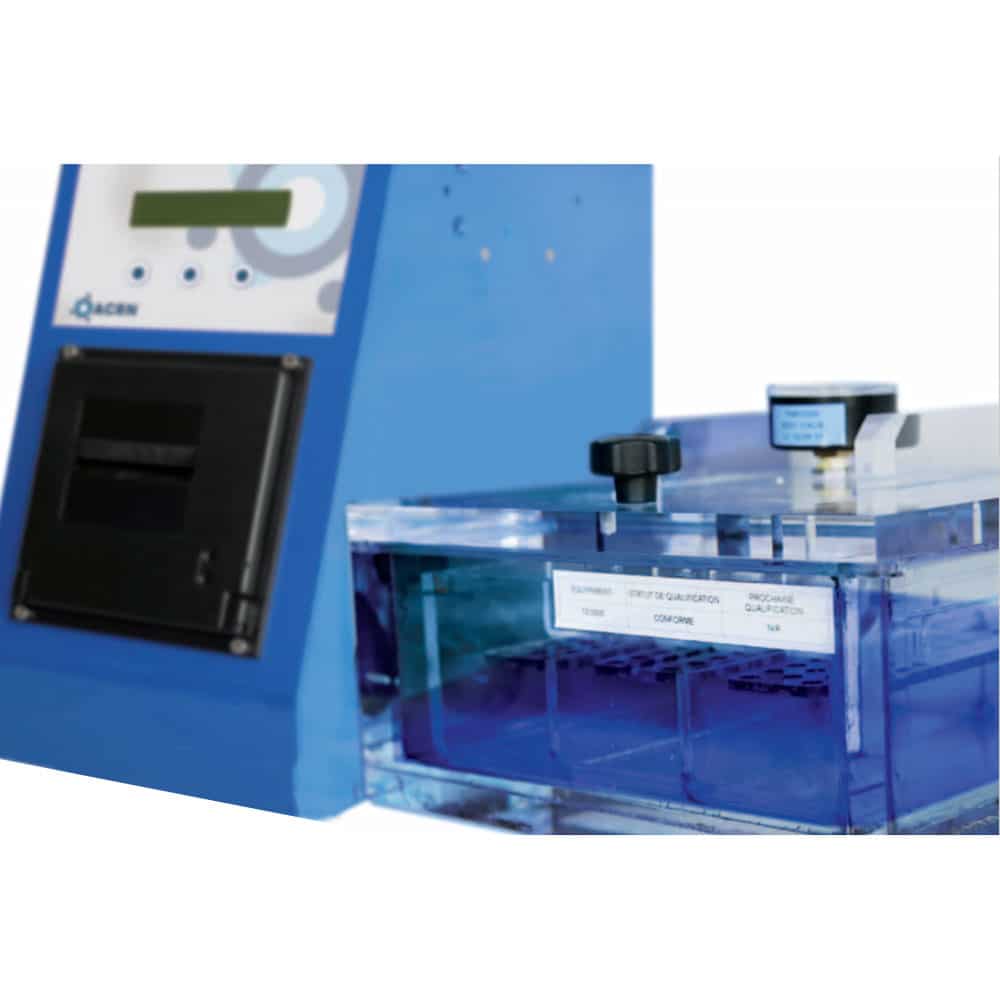

CTEX-Bi Leak test box

Pharmaceutical Leak Detector

It makes it possible to test by vacuum, in particular to the migration of a tracer product, called methylene, the tightness of samples such as blister packs or pouches, yogurt, trays, mechanical assemblies, etc..

This model is available with a vacuum pump system for vacuuming.

Description

Benefits

- Fast, ergonomic and easy to use

- Visual reading

- Reliable and economical

- Adapted to the production envrionment / Robust

- Test on receipt of raw materials, in production, before shipment

- Pressure sensor in the control box

- Traceability by a printed time-stamped ticket containing the test information or by data export software

- Sample recovery using a drip tray removable

- Graduated ruler for good test repeatability

- Specific arrangement

Technical information

| Box | Transparent PMMA chamber on hinge |

| Range of measurements and accuracy | From -0.1 to -0.85 Bar as standard. Accuracy + / -2 % Fully controlled by a microprocessor card |

| Useful dimensions | It depends on the size of box. |

| Reading the depression | Digital display : ergonomic menu with only 3 keys. |

| Units | Bar, Psi |

| Power supply | – On compressed air 7 bar / – Vacuum pump |

| Weight | Depends box defined |

| Thickness | 20, 25 or 30 mm depending on the RDM study |

| Depression adjustment | Solenoid valve |

| Printing | Printer embedded tickets for ticket stamped |

| Depression time | Adjustable delay from 0 to 4 000 s |

| Principle of the test | Visual |

| Temperature | From 0 to 40°C |

| Standards | IATA, ASTM D6653, ASTM D4991, ASTM D5094, ASTM D4169, EN 14401, DIN55528 (Part 1, 2, 3, 4, 5) |

| Programming | 8 independent programs (time/ depression) that can be liked together |

Options

| Decrease in depression time (vacuum pump, more powerful venturi) |

| Model without printer |

| Software for acquisition data bit by bit towards any PC software |

| Ergonomic drip tray |

| Very Specific arrangement |

| Vacuum pump replacing compressed air |

Delivered with:

A calibration certificate LNE / COFRAC