Pouch Crush ATS-XP

Test the strength of your pouches up to 2 tons

The ATS-XP is used to check the seal strength of plastic or metalloplastic packaging such as pouches and bags directly on the edge of the production line or in the laboratory. It can be used in addition to the devices to test the welding of ATS tubes.

Description

Why test your weld ? During heat sealing, defects in the weld may appear due to electrode temperatures and the presence of impurities. The implementation of a reliable control of the weld integrity, verified by the absence of leaks or microleaks under the effect of a crushing force applie to the sample to be tested, is essential.

It’s a simple, fast , affordable and completely test reliable deployed in various packaging manufacturers.

The ATS-XP is suitable for all kinds of bags and pouches.

ACRN, having 20 years of experience in this activity, will can help us for these settings.

Two tests

The benefit of the product it’s can realize two different tests thank to this numeric display in which the user can vary the supporting force and the test time.

- Micro-leak test which increases with pressurization and causes bursting

- Burst test to determine the strenght of welds

Benefits

Simple, fast, reliable and completly repeatable

Numeric display easy to use

Precise leak localization

Removable lower plate for placing products

Specific housing on request for precise adjustment of the positioning of your samples ensuring very good repeatability of your measurements

Realization of your tests in complete safety thanks to the transparent polycarbonate safety cover preventing its opening during the test and the start of a cycle once opened

Damping at the top and bottom end of stroke

Time-stamped receipt printer

Options

| Specific housing for sample |

Informations complémentaires

| Pouch Crush | Pouch crush PVC on rigid metal frame, transparent unbreakable polycarbonate casing painted mild steel support frame |

|---|---|

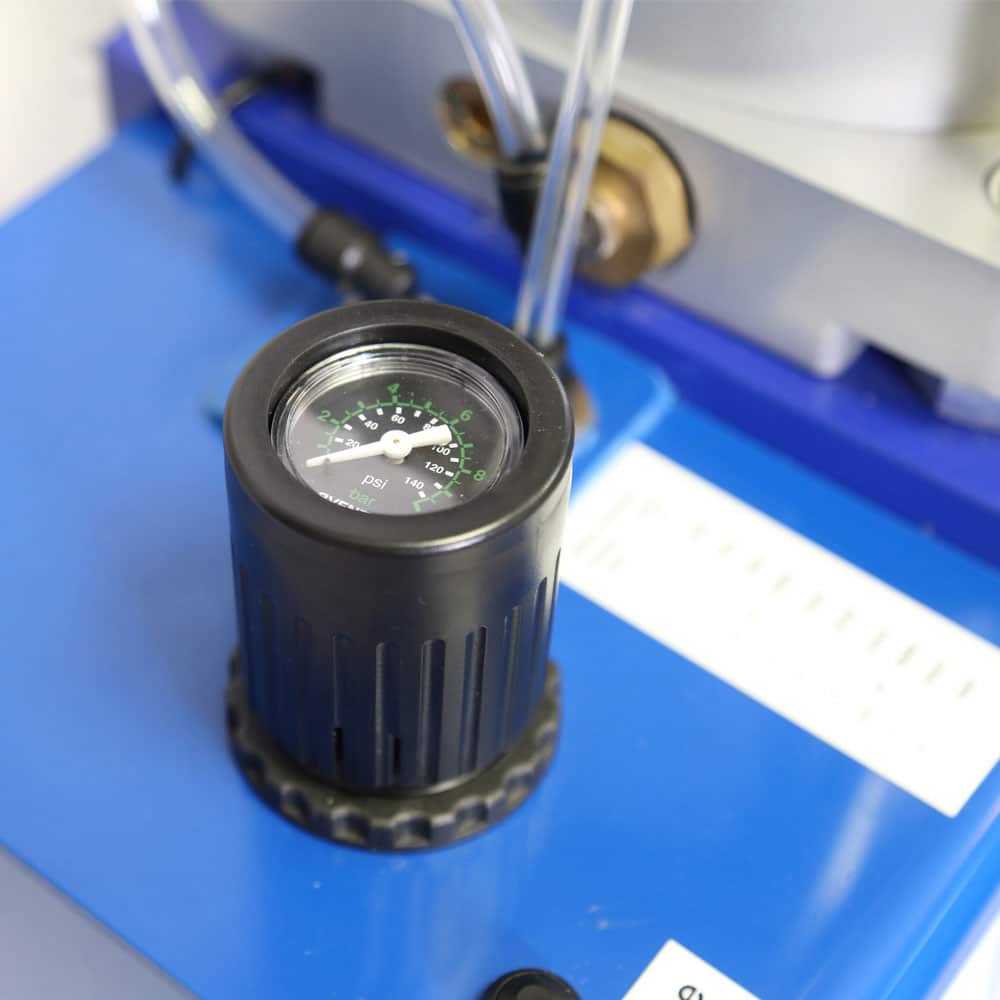

| Power supply | Compressed air from 0 to 10 bars |

| Autoplay | Electronic force sensor with 3N of resolution |

| Pressure force | From 400 kg to 2 400 kg |

| Time delay | Electronic timer up to 999 seconds |

| Connection power supply | Connection to a compressed air network by Rislan tube 8 mm outside diameter |

| Traceability | Time-stamped receipt printer |

| Support plate diameter | 200 mm |

| Useful Dimensions | L400xD340xH550mm |

| Digital output | RS232 |