RepeaTork motorized torque meter

The torquemeter for screwed packaging

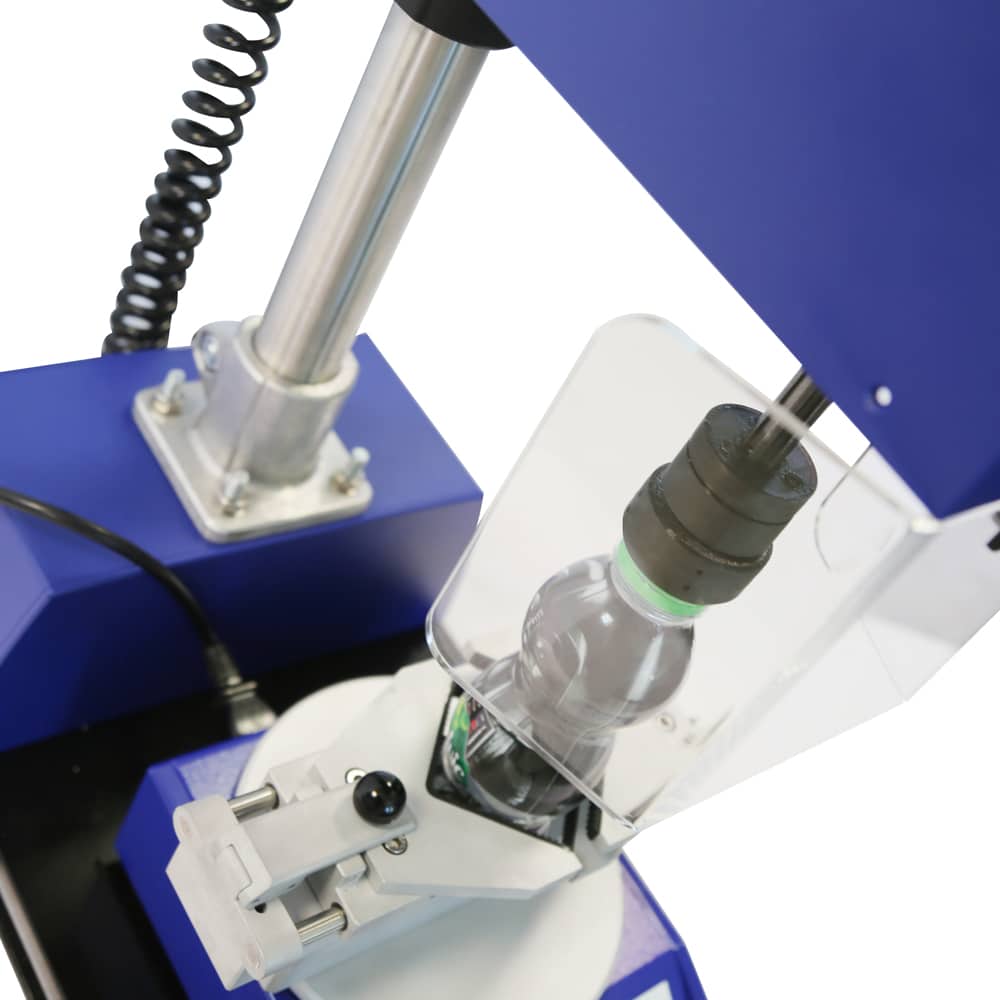

The RepeaTork is a motorized torque meter designed to measure the unscrewing torque of screwed caps and pumps accurately and reliably. It includes all the functions of a conventional tabletop torquemeter, plus motorization. It features three operating modes: simple screw/unscrew mode, a screw/unscrew mode with angle or torque, and a torque control mode for opening and screwing back with torque.

Repeatork is a fast, simple and totally repeatable solution deployed by many packaging manufacturers. It enables manufacturers to quickly and easily improve the quality of their unscrewing torque measurements and consolidate their quality assurance.

It’s also affordable and helps reduce RSI linked to repetitive operator movements.

Description

The Repeatork is a motorized torque meter that eliminates the human effect when unscrewing the cap. It ensures perfect centering, constant speed and optimum cork grip. The torque values obtained are reliable and repeatable.

It is designed for packaging such as bottles, flasks, pump containers, cans, perfumes, screw-top cans …. Agri-food, pharmaceuticals, cosmetics, petrochemicals…

Operation and set-up

The Repeatork incorporates all the functions of a conventional tabletop torquemeter, with the addition of motorization:

- Simple screwing/unscrewing mode: the operator unscrews or screws at a preset speed and recovers the measured torque value.

- Angle or torque screwdriving/unscrewing mode: set angle, torque and speed thresholds in both directions to suit your control protocols. It recovers the value.

- Open torque control then tighten to torque mode: ideal for testing finished products at the line’s edge, this mode allows you to tighten to the target torque after unscrewing, without having to remove the test sample.

Benefits

Repeatable measurements to neutralize the human effects of manual torquemeters.

The equipment is compatible with ACRN manual torquemeters of all generations, past and future.

The RepeaTork is designed to handle the diversity of your samples: an innovative clamping system with interchangeable “FAST” jaws enables product diversity to be handled in record time, while guaranteeing optimal cap gripping without deformation.

Fast control to free up maximum operator time.

Affordability.

A reduction in musculoskeletal problem

ACRN at your side for your project

Simply send us examples of each sample to be tested, including the largest and smallest. ACRN can offer you solutions for lower clamping and upper drive.

The Repeatork will adapt to your product samples (new packaging, new closures). If necessary, new jaws can be ordered.

ACRN will offer more advanced and personalized support for the transition from manual to motorized measurements (impact study, etc.).

Informations complémentaires

| Dimensions | W300 x D500 x H770 mm |

|---|---|

| Weight | 20 kg |

| Maximum cap height | 250 mm (optional up to 530 mm) |

| Maximum plug diameter | 140 mm |

| Power supply | 110V AC / 230V AC – 50 Hz / 60 Hz |

| IP Classification | IP52 |

| Noise level | <40 dB |

| Environment | From 4° to 37°C |

| Guarantee | 2 years |